Building and maintaining an FPV drone requires more than just buying the right parts—you also need to know how to solder them together. Soldering is the backbone of drone assembly. A single weak solder joint can cause signal loss, motor desync, or even a mid-air crash. On the other hand, clean and strong soldering ensures reliable power delivery, long-lasting connections, and safe flights.

In this 2025 FPV soldering guide, we’ll cover everything you need to know—from the essential tools and materials to step-by-step soldering techniques, common mistakes, safety precautions, and even pro-level tricks. Whether you’re just starting out or already an experienced FPV pilot, this guide will help you achieve professional-level results.

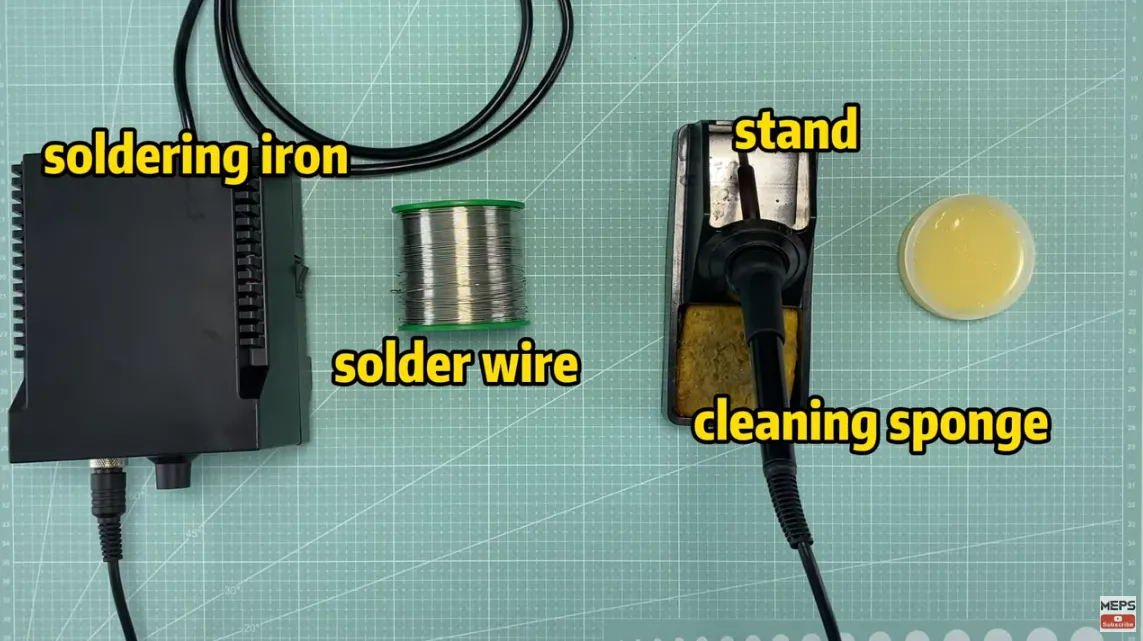

Essential Tools for Soldering

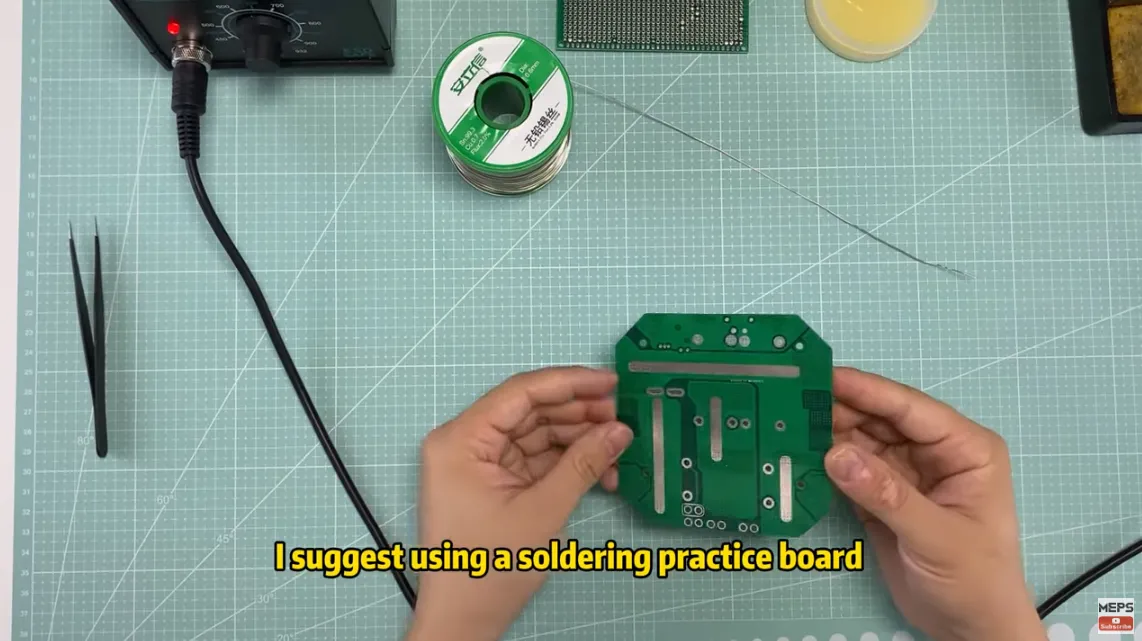

Before diving into the soldering process, it’s essential to familiarize yourself with the necessary tools. From left to right, you’ll need a soldering iron, solder wire, a cleaning sponge, and a stand. Opting for an adjustable-temperature soldering iron is recommended, as higher wattage leads to faster heating. Additionally, choose solder wire with built-in flux for optimal results. Beginners may find it helpful to practice soldering on a soldering practice board.

Soldering Iron / Soldering Station

A temperature-controlled soldering iron is the most important tool in your kit.

- Recommended Temperature Range: 350–400℃ (662–752℉).

- Tip Shapes:

- Conical tip → precision work (signal wires, small pads).

- Chisel tip → power pads (ESC, battery leads).

Solder Wire

The type of solder wire you choose affects the ease of soldering and the quality of your joints.

| Type | Melting Point | Pros | Cons | Best For |

|---|---|---|---|---|

| Sn63/Pb37 | ~183℃ | Low melting point, shiny joints, beginner-friendly | Contains lead, not eco-friendly | Beginners, ESC pads |

| Lead-free | ~217℃ | Safer, RoHS compliant | Requires higher heat, harder to flow | Advanced builders, eco-conscious users |

Pro Tip: For beginners, Sn63/Pb37 is easier to use and produces more reliable joints.

Flux & Desoldering Tools

- Flux: Helps solder flow evenly and prevents oxidation.

- Desoldering Pump/Wick: Useful for removing excess solder or fixing mistakes.

Extra Accessories

- Tweezers and a magnifying glass for precision.

- “Third hand” tool for holding wires and components.

- Heat shrink tubing and electrical tape for insulation.

Melt the Solder Joints

If you want solid solder joints, the first thing to do is to melt them. Yes, you heard that right melt them. Many weak solder joints happen because the temperature is too low which leads to insufficient melting of the tin. Therefore the temperature of the soldering iron tip is very important.

Key Points for Solid Solder Joints

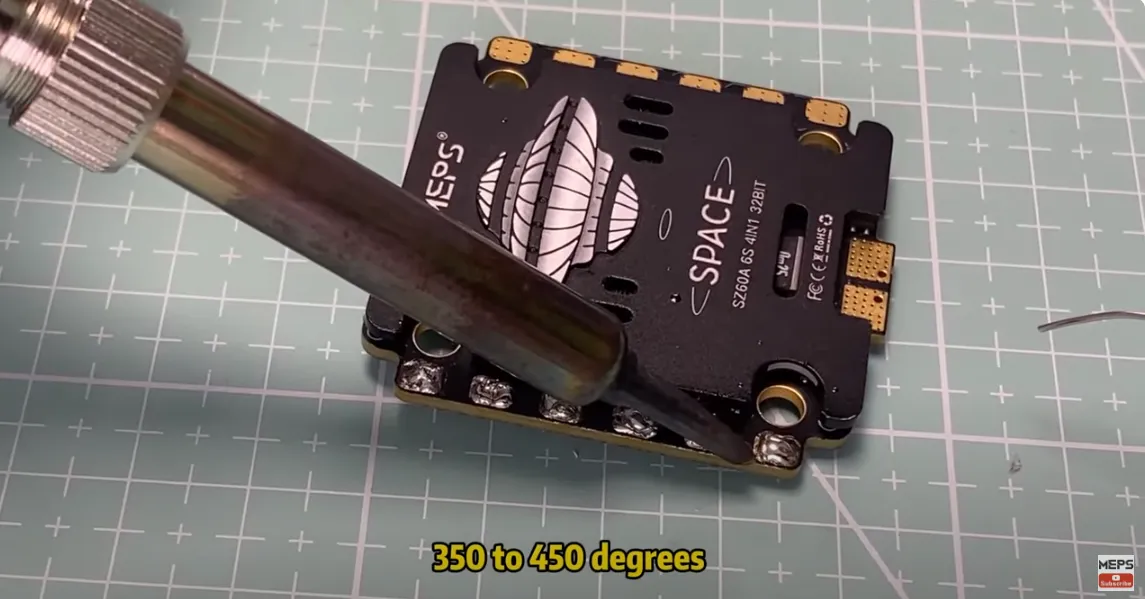

Optimal Temperature Control: Achieving solid solder joints begins with proper temperature control. Ensure that the soldering iron tip reaches the appropriate temperature to melt the solder effectively. Larger solder pads, such as ESC pads, require temperatures ranging from 350 to 450 degrees, while smaller pads like FC pads should be heated above 300 degrees. Insufficient melting due to low temperatures can result in weak solder joints.

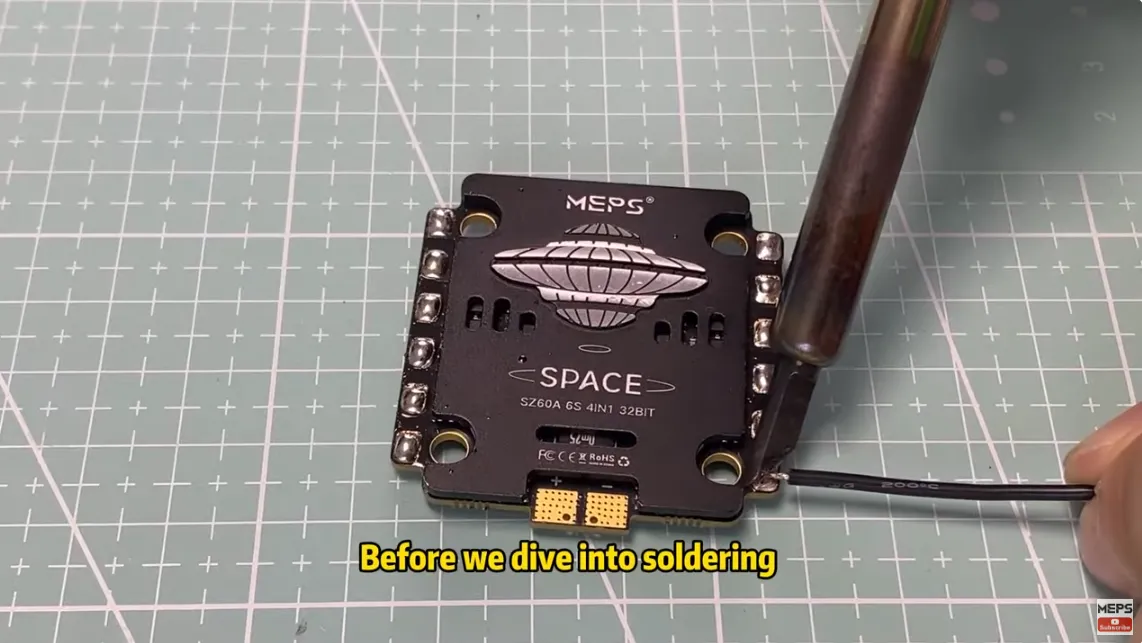

Preparation of Soldering Iron Tip

To facilitate heat transfer, it’s crucial to add a bit of solder to the soldering iron tip before soldering. This helps ensure proper melting of the solder when the iron comes into contact with the pads.

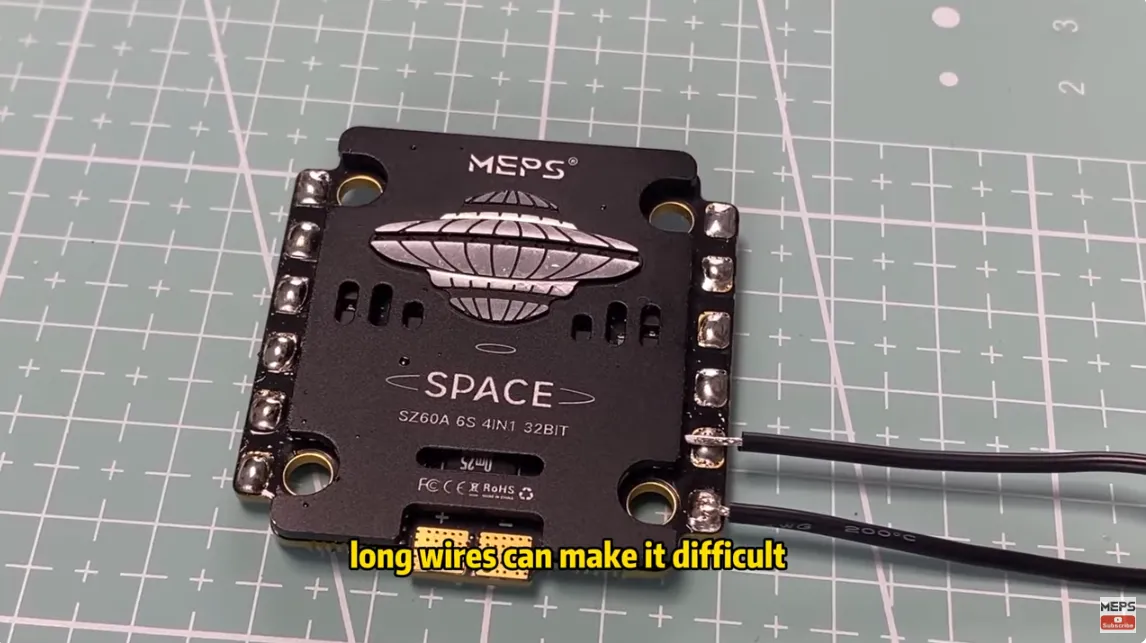

Correct Wire Length

Pay attention to the length of the wires being soldered. Using excessively long wires can make it challenging to cover the entire wire properly. Ensure that you cut the wires to the appropriate length before soldering to achieve optimal results.

Soldering Key FPV Drone Components

Motors to ESC

- Cut motor wires to the correct length—too long adds weight, too short causes tension.

- Tin the ESC pads and wires before joining.

- Press wire to pad, apply heat briefly, then remove.

ESC to Flight Controller

- Use silicone wires (they’re heat resistant and flexible).

- Double-check polarity and signal wire mapping.

- Secure wires with tape or zip ties to prevent strain.

Power Leads and Capacitors

- Use thicker gauge wires for battery leads (12–14 AWG).

- Add a low-ESR capacitor near the battery pads to reduce voltage spikes and protect electronics.

- Make sure to reinforce with heat shrink tubing.

VTX and Receiver Modules

- These pads are small and delicate—use a fine soldering tip.

- Apply flux to help prevent bridging.

- Avoid overheating to protect sensitive chips.

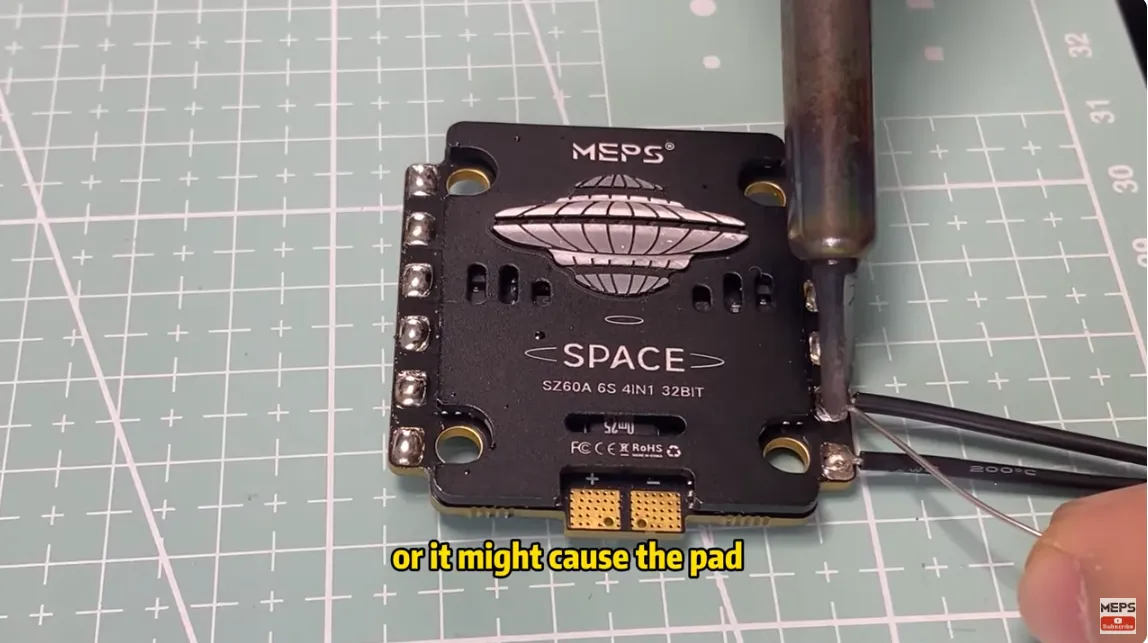

Avoid Prolonged Heat Exposure

To prevent damage to the pads and achieve perfect joints, avoid keeping the soldering iron on a single pad for too long. Prolonged heat exposure can cause the pad to detach, making it difficult to fix. Once the solder has melted, release the iron promptly to ensure a perfect joint.

By following these key points and practicing proper soldering techniques, you can achieve solid solder joints essential for reliable electrical connections in your FPV drone build.

Common Soldering Mistakes and How to Fix Them

Cold Joints

- Signs: Dull, grainy appearance, weak connection.

- Fix: Reheat with proper temperature, add flux, and let the solder flow smoothly.

Excess Solder

- Signs: Large blobs of solder, potential short circuits.

- Fix: Use desoldering wick or a pump to remove extra solder.

Overheating Pads

- Signs: Pad lifts from the PCB, component damage.

- Fix: Lower the temperature, limit contact time to 2–3 seconds per joint.

Safety Tips for FPV Drone Soldering

- Work in a well-ventilated area or use a fume extractor.

- Always return the soldering iron to its stand—never leave it unattended.

- Wear safety glasses to protect against splashes.

- Never solder with a LiPo battery connected to the circuit.

Pro-Level Soldering Tips (2025 Edition)

Once you’ve mastered the basics, these advanced tips will improve durability and make repairs easier.

- Soldering Ultra-Thin Wires: Use low heat and fine tips when working with VTX and receiver signal pads.

- Fixing Lifted Pads: Bridge the connection using jumper wires.

- Reinforcement: Use heat shrink tubing or UV glue to strengthen joints and reduce vibration-related stress.

- Wire Management: Route wires neatly to avoid interference and airflow blockage.

FAQ

1. What is the best soldering iron for FPV drone building in 2025?

A temperature-controlled soldering iron with at least 60W of power is recommended. Popular choices include Hakko, TS100/TS101, or Pinecil.

2. What temperature should I use for soldering FPV motors?

350–380℃ is ideal. For thick power wires, you may go up to 400℃.

3. How do I avoid cold solder joints?

Always tin wires and pads, use flux, and apply the iron until solder flows smoothly.

4. Can I use lead-free solder for FPV drones?

Yes, but it requires higher heat and more skill. Beginners usually prefer Sn63/Pb37 solder.

5. How do I repair a broken solder pad on a flight controller?

Use a jumper wire to reconnect the signal or power trace to another pad or component pin.

Conclusion

Soldering is a core skill in FPV drone building. Strong joints ensure efficient power delivery, clean signals, and safe flights. With the right tools, preparation, and practice, anyone can achieve professional results—even as a beginner.

If you’re upgrading your FPV build in 2025, make sure you also use high-quality components. A perfect solder job is only as good as the parts you connect.