In every multirotor drone, the FPV motor is the driving force that spins the propellers and makes flight possible. Within the FPV (First-Person View) community, motors are often considered the “heart” of the aircraft, as even small design differences can have a noticeable impact on weight, responsiveness, efficiency, and overall power. In other words, the choice of FPV motors plays a decisive role in how your quadcopter will perform in the air.

Before selecting any FPV motors, always start with two fundamentals:

- Your drone’s all-up weight (AUW)

- Your frame and propeller size

These two factors determine how much thrust your motors need to generate and how efficiently your quadcopter motor system will perform.

Note that AUW is not just the weight of the frame, but also includes components such as the flight controller, PDB, cables, drone motors, drone esc, batteries, fpv camera and transmitter, and other components.

With these two key pieces of information, you can begin narrowing down your motor options. In the sections below, we’ll explore the fundamental motor parameters and practical considerations that will help you choose the right setup for your FPV build.

Introduction to FPV Drone Motors

What is FPV Drone Motor?

FPV drone motors are one of the most important power components. They are specially designed motors for FPV drones, aimed at providing the thrust, speed, and maneuverability required by FPV drones. These motors are crucial to the performance of drones, as they enable FPV drones to achieve rapid acceleration, precise turns, and stable hovering. Given the high-performance requirements of applications such as FPV racing, freestyle, and aerial acrobatics, FPV drone motors are designed with a focus on power, efficiency, and precision.

Brushless Motor vs. Brushed Motor

Brushless and brushed motors are the two main motor types used in FPV drones.

Brushless motors dominate modern FPV drones because they are:

- More efficient

- More durable

- Capable of higher RPM and torque

Brushed motors still appear in toy drones and ultra-cheap whoops due to lower cost, but they wear out quickly and lack precision.

For any serious FPV drone build, brushless FPV motors are the only practical choice.

If you want to learn more about the differences between brushed and brushless motors, check out the guide Brushed vs Brushless Motor: What’s the Difference?

How DO FPV Drone Motors Work?

FPV drone motors consist of two main parts: the stator (stationary coils) and the rotor (magnets that spin). When the electronic speed controller (ESC) sends signals to the stator, it creates a magnetic field that makes the rotor turn. By adjusting voltage and timing, the ESC controls the motor’s speed and direction.

Because these motors are brushless, they reduce friction, last longer, and run more efficiently. This design provides strong thrust, quick response, and better flight times — ideal for racing, freestyle, and aerial tricks.

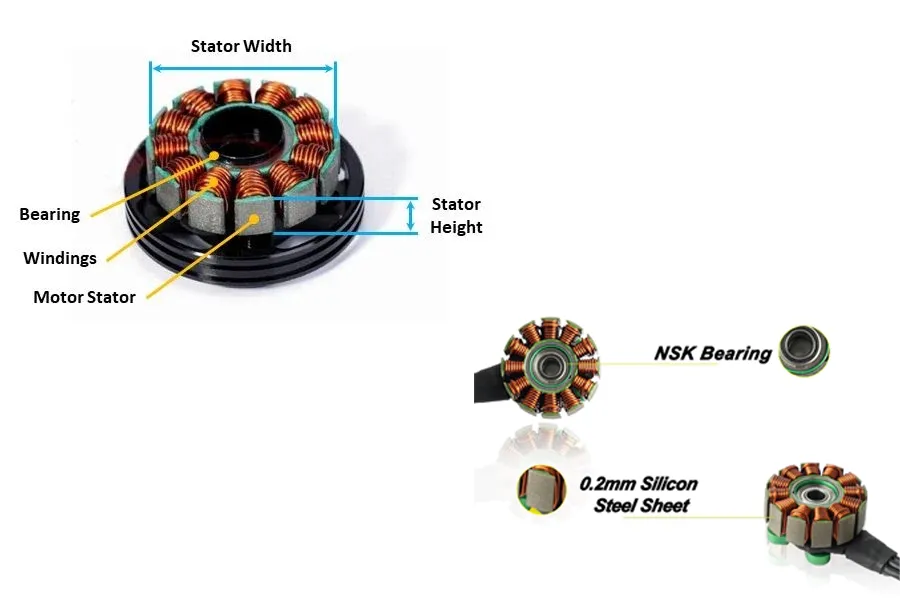

Structure of FPV Drone Motors

An FPV drone motor is a precision-built brushless motor made up of multiple components working together to deliver thrust, efficiency, and durability. Its main elements include the stator with copper windings, the rotor (bell) with magnets, the shaft and bearings for smooth rotation, and supporting features like flux ring, air gap, laminations, and motor bell material that determine performance, durability, and efficiency.

The following table breaks down the main parts of an FPV motor and their specific roles. If you want a deep-dive into motor technology and advanced tuning, check out our full guide on What is the Structure of FPV Drone Motor?

FPV Drone Motor Structure & Functions

| Component | Function |

|---|---|

| Stator & Windings | Generates electromagnetic fields that drive rotation; wire gauge and turns impact torque and KV. |

| Rotor (Bell) & Magnets | Houses permanent magnets; magnet strength (e.g., N52) affects torque and smoothness. |

| Shaft | Connects motor to propeller; designs include solid, hollow titanium, or hybrid. |

| Bearings | Ensure smooth rotation; larger or ceramic bearings affect durability and noise. |

| Air Gap | Distance between stator and magnets; smaller gap increases power but reduces efficiency. |

| Flux Ring | Enhances magnetic flux return, improving torque and efficiency. |

| Motor Bell Material | Aluminium alloy (7075/6082) affects crash resistance and weight. |

| Bottom Design | Closed vs. naked base; impacts weight, dirt resistance, and ease of cleaning. |

What are N and P in an FPV Motor?

Motor labels like 12N14P describe internal geometry:

- N = number of stator poles

- P = number of rotor magnets

This configuration affects efficiency, smoothness, and torque delivery.

What is KV on Brushless FPV Motors?

KV defines how fast a motor spins per volt with no load.

For example, if you choose a 1000KV motor and use a 12V lithium battery to power it, the total speed will be 1000*12=12000 RPM (no load)

Once a propeller is attached, RPM drops due to air resistance. Higher KV motors spin faster but draw more current; lower KV motors provide more torque and efficiency. This is why we tend to see larger propellers used with lower KV motors, while smaller and lighter propellers are better suited for higher KV motors. It is important to choose the right KV for your drone.

Brushless Motor KV Chart:

| KV Rating | Best For | Characteristics |

| 1000-1600KV | 7″-10″ Long-range | Low RPM, high efficiency, longer flight time |

| 1600-2200KV | 6″-7″ Cinematic & LR | Moderate power, balance of speed & efficiency |

| 2200-2700KV | 5″ Freestyle & Racing | Fast response, powerful, but higher power draw |

| 2700-3500KV | 4″ Racing | High-speed, aggressive performance |

| 3500-4500KV | 3″ & Whoops | High RPM, quick acceleration, short flight time |

- Lower KV = More torque & efficiency

- Higher KV = Faster response & more power draw

If we pair a larger propeller with a high KV motor, more torque is needed to spin faster. While generating the required torque, it draws more current and generates too much heat. This overheating can also damage your motor.

Want to understand KV in depth? Check out our detailed guide: What is KV in Motor, and help you choose the best KV for 4s & 6s FPV motors.

How to Choose FPV Drone Motors?

Step 1: Estimate Your All-Up Weight (AUW)

Start by estimating your drone’s all-up weight, not just the frame.

Include:

- Frame

- Motors and ESC or AIO

- FPV system (analog or digital)

- Battery

- Camera or GoPro

- Antennas, screws, TPU parts

Motor thrust requirements are based on total flying weight, not dry weight. Underestimating AUW is one of the fastest ways to end up with underpowered or overheating motors.

Step 2: Lock in Frame Size and Propeller Size

Your frame size determines the maximum propeller size, and prop size defines how much load the motors must handle.

The frame should ideally be able to support propellers up to one-third of its size. By balancing lift and stability for effective flying, this proportionality maximizes aerodynamic performance.

Common examples:

- Tiny whoop frames → 31–40mm props

- 3-inch frames → 3″ props

- 5-inch frames → 5″ props

- 7–10 inch frames → large, low-RPM props

Once these factors have been determined, you can begin selecting an FPV drone motor. When choosing an FPV drone motor, the most critical considerations are the motor’s size, thrust, and thrust-to-weight ratio.

Step 3: Choose FPV Drone Motor Size Based on Prop Load

Motor size refers to the stator size, not the motor can itself. The stator determines how much torque the motor can produce.

General rule:

- Small props → smaller stators, higher RPM

- Large props → larger stators, higher torque

Examples:

- 1103 / 1202 → Tiny whoops

- 1404 / 1505 → 3-inch builds

- 2207 / 2306 → 5-inch freestyle or racing

- 2808 / 3110 → 7–10 inch long-range or cinematic

If the stator is too small, the motor will struggle, overheat, and lose efficiency.

Understanding Motor Numbers:

Brushless motors are usually labeled with four digits (e.g., 2205):

- The first two digits = stator diameter (mm)

- The last two digits = stator height (mm)

- Taller stator → more power at high RPM

- Wider stator → more torque at low RPM

Taller stators also help dissipate heat, while wider stators increase efficiency thanks to more copper and iron.

Choosing the Right Motor Size:

Your frame size limits propeller size, which in turn determines motor size and KV. In most cases, knowing the frame size is enough to guide your motor choice. Always check motor thrust data to ensure current draw stays within safe limits.

Here’s a general guideline (assuming a 4S LiPo battery):

| Frame Size | Prop Size | Motor Size | KV Rating |

| 150mm or smaller | 3 inch or smaller | 1306 or smaller | 3000KV or higher |

| 180 mm | 4 inch | 1806 | 2600KV |

| 210 mm | 5 inch | 2204 – 2206 | 2300KV – 2600KV |

| 250 mm | 6 inch | 2204 – 2206 | 2000KV – 2300KV |

| 350 mm | 7 inch | 2208 | 1600KV |

| 450 mm | 8/9/10 inch | 2212 or large | 1000KV or lower |

If you want to know more details, please check out the blog of What Size FPV Motor Should I Choose?

2207 vs. 2306 – Which Size is Better?

| Feature | 2207 Motor | 2306 Motor |

| Power Output | High | Medium |

| Efficiency | Lower | Higher |

| Response Time | Faster | Smoother |

| Best For | Aggressive Freestyle & Racing | Smooth Cinematic Flying |

- Choose 2207 if you want raw power and responsiveness.

- Choose 2306 if you prefer stability and smooth flight performance.

Step 4: Verify Thrust-to-Weight Ratio

For any multirotor build, the thrust-to-weight ratio is a key factor that determines stability, agility, and overall flight performance. As a general rule, your motors should generate at least 50% more thrust than the total weight of your drone.

- With a higher thrust-to-weight ratio, the drone gains more agility and acceleration, but it can also become harder to control.

- If the motors produce less thrust, the drone may struggle to take off, respond poorly to controls, or lose stability in even light wind.

| Motor Type | Weight Range |

| 2″ TinyWhoop | 5-10g |

| 3″ Cinewhoop | 10-20g |

| 4″ Toothpick | 15-25g |

| 5″ Racing | 25-35g |

| 6-7″ Long Range | 35-50g |

Build Material:

Steel Shaft Motors → More durable but heavier.

Aluminum (7075-T6) → Lightweight, durable, best for racing.

A safe baseline:

- Total max thrust ≥ 2× drone weight

For example, if your quadcopter weighs 1 kg, the motors should provide a total of at least 2 kg of thrust at full throttle — about 500 g per motor.

For racing drones and freestyle drones, the thrust-to-weight ratio should be significantly higher than the examples mentioned above.

Recommended by flight style:

- Long range / cinematic: 3:1 – 4:1

- Freestyle: 5:1 or higher

- Drone racing: 5:1–7:1+

Always check motor + prop thrust test data, not just motor specs alone.

Check out the blog on How to Calculate Drone Motor Thrust to learn how to select a motor based on thrust requirements.

Step 5: Select KV Based on Battery Voltage and Style

KV should be chosen after battery voltage is decided. The higher the voltage, the faster the drone motor spins and the more current it draws.

Typical pairings:

- 4S → higher KV

- 6S → medium KV

- 8S+ → lower KV

| Battery Voltage (LiPo) | Best KV Range |

| 3S (11.1V) | 3000-4500KV |

| 4S (14.8V) | 2300-2700KV |

| 5S (18.5V) | 1800-2300KV |

| 6S (22.2V) | 1600-1950KV |

Example:

- 4S + 2300- 2700KV is standard for 5″ FPV racing drones.

- 6S + 1600- 1950KV is common for high-efficiency freestyle drones.

Then fine-tune by flying style:

- Racing → higher KV for faster acceleration

- Freestyle → balanced KV for control and punch

- Long range → lower KV for efficiency and cooler motors

You can limit output in Betaflight, but you can’t create torque that isn’t there.

How to Choose an FPV Drone Motor KV for Your Flying Style?

Different flying styles—racing, freestyle, cinematic, or long-range—demand unique motor characteristics in terms of KV rating, torque, size, and efficiency. Below is a breakdown of which FPV motor suits each flying style:

- Racing Drones: Use high-KV motors (e.g., 2207 2450KV–2750KV) that provide fast RPM and explosive throttle response. These motors are lightweight and designed for quick acceleration, sharp turns, and high top speed. However, they consume more current, so efficiency takes a backseat to performance.

- Freestyle Drones: For freestyle (tricks, dives, smooth flow flying), choose mid-KV motors (e.g., 2306 1900KV–2100KV on 6S). These offer the right balance between power, control, and flight time. The slightly larger stator size (2306/2207) gives more torque for handling heavier props, making it easier to recover from dives or power loops.

- TinyWhoop / Micro Drones: These ultra-small quads rely on brushed or small brushless motors (0802–1202 size, 16000KV–25000KV). The focus is on lightweight design, quick response, and indoor safety. High-KV micro motors ensure agility in tight spaces, though they trade efficiency for speed.

- Cinewhoop (3–4 inch)

Cinewhoops need low- to mid-KV motors (1404–1507, 2800KV–3800KV on 4S) to spin larger ducted props smoothly. The priority is stable, vibration-free footage for carrying a GoPro or DJI O3 Air Unit. These motors emphasize torque and smooth throttle response over raw speed. - Long-Range Drones: For endurance and exploration, use low-KV, large stator motors (2507, 2806.5, 1300KV–1700KV on 6S). These provide high efficiency and torque, enabling long flight times with heavy Li-Ion packs. The goal is steady cruising, not aggressive acrobatics.

Quick Reference Table – FPV Drone Motor Selection

| Flying Style | Motor Size & KV (Typical) | Key Features |

|---|---|---|

| Racing | 2207 / 2306, 2450–2750KV | High RPM, explosive speed, sharp response |

| Freestyle | 2306 / 2207, 1900–2100KV (6S) | Balanced power, torque for tricks, flow control |

| TinyWhoop / Micro | 0802–1202, 16000–25000KV | Lightweight, agile, safe for indoors |

| Cinewhoop (3–4”) | 1404–1507, 2800–3800KV (4S) | Smooth, stable thrust for cinematic footage |

| Long-Range | 2507–2806.5, 1300–1700KV (6S) | Efficiency, endurance, torque for heavy packs |

Pro Tip: When choosing an FPV drone motor, always match prop size, battery voltage (4S/6S), and flying style. A well-matched motor setup improves not only performance but also flight time and reliability.

Step 6: Confirm ESC Current Capacity

High-performance FPV motors pull serious current—especially in racing setups.

Make sure:

- ESC continuous current rating matches motor demands

- Burst current can handle full-throttle punches

Many “motor failures” are actually ESC overloads in disguise.

Step 7: Consider Weight and Responsiveness

For freestyle and racing, motor weight matters more than beginners expect.

- Lighter motors → faster throttle response

- Heavier motors → more inertia, smoother feel

Two motors with the same stator size can feel completely different in the air.

Recommendations of FPV Drone Motors

MEPS Neon 2207 FPV motor Racing Drone Motor

For pilots looking for a well-balanced motor that delivers both power and efficiency, the MEPS Neon 2207 FPV motor is an excellent choice. With its optimized 2207 stator design, it provides high torque for freestyle moves and stable thrust for racing. The motor’s durable construction and responsive performance make it suitable for both beginners aiming to grow their skills and advanced pilots pushing their limits.

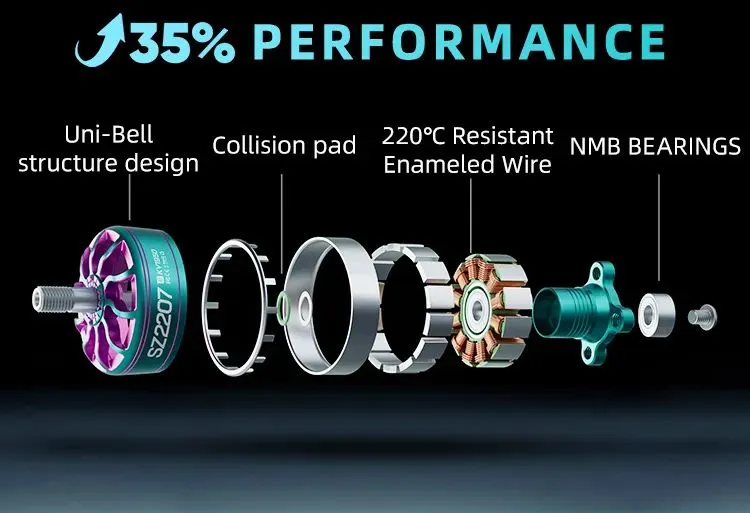

MEPS SZ2207 Drone Motor 5-inch Racing Drone

The MEPS SZ2207 FPV motor is a standout choice for 5-inch racing drones. Designed with performance in mind, this motor offers a great balance of power and efficiency, making it ideal for competitive FPV pilots.

With a lightweight design and high-quality materials, the SZ2207 delivers rapid acceleration and excellent control, crucial for tight turns and high-speed maneuvers. Its responsive throttle and smooth power curve make it a reliable FPV drone motor for both racing and freestyle flying.

Overall, the MEPS SZ2207 is a top-tier FPV motor that combines durability with the agility needed for 5-inch racing drones. Whether you’re competing or just flying for fun, this motor won’t disappoint.

Thobby F1404 Tiny Trainer Build/Micro Long Range Drone Motor

The Thobby F1404 FPV motor is a standout choice for tiny trainer builds and micro long-range drones. With a 3800KV rating, it offers a perfect blend of responsiveness and efficiency, making it ideal for ultralight setups.

Weighing in light, this FPV motor enhances agility and flight time, crucial for long-range adventures and tight maneuvers. The F1404’s well-rounded performance ensures smooth, consistent power delivery, whether you’re cruising at a distance or pushing your drone to the limits in a race.

MEPS SZ1103 Brushless Motor for Whoop Drone

The MEPS SZ1103 FPV motor is specifically engineered for 2-inch and 3-inch micro drones or whoop drones, offering a perfect mix of power and precision. This motor shines in delivering smooth, responsive performance, making it ideal for tight spaces and agile maneuvers.

With a robust build and efficient design, the SZ1103 provides ample thrust while maintaining excellent flight times. It’s well-suited for both freestyle flying and precise indoor navigation, thanks to its balanced torque and quick throttle response.

In summary, the MEPS SZ1103 is an outstanding FPV drone motor for pilots looking to enhance their micro drone setups. It’s a reliable and versatile choice that excels in both performance and efficiency.

Matching of FPV Motors and Other Components

Match Propellers to Motors

The motor you choose must be compatible with your propeller size and pitch. Larger or higher-pitch props generate more thrust but demand more torque, pairing best with low-KV motors. Smaller or lower-pitch props require less torque and work well with high-KV motors, favoring speed over lift.

Material and blade count also affect performance—carbon fiber props offer rigidity and stability, while plastic props provide flexibility and forgiveness in crashes. More blades can increase thrust but also add drag, reducing efficiency.

Match Battery to Motor

Voltage and current are critical when pairing batteries with motors. Higher-voltage motors can reach higher RPMs but require batteries with sufficient cell count (e.g., 6S or 12S). Current draw affects torque and heat; higher draw demands batteries that can supply consistent power without rapid depletion.

Mismatched voltage or current can lead to poor performance, overheating, or even component failure. Always ensure the motor’s rated voltage and current align with the battery’s capabilities.

Read the guide on Matching the FPV Motor and Battery for Your Drone to learn more about choosing batteries based on motors.

Match ESC to Motor

The ESC receives flight controller commands and regulates the motor output current. It is the core driver for motor operation. Proper ESC matching prevents burnout risks and enhances response speed and system efficiency.

The ESC’s rated current must exceed the motor’s maximum continuous current by 20–30%to handle instantaneous current spikes. Take the MEPS SZ2207 V2 motor 1750KV as an example. When paired with 4942 propellers, the maximum peak current is 33.3A when the throttle is pushed to the maximum, i.e., when the pull reaches 100%.

- 33.3*(1+30%)=43.29A

- So the rated current of the ESC you choose should be above 45A.

Motor Mounting Pattern

For 22xx, 23xx, and 24xx motors, the most common mounting patterns (hole distances) are 16x19mm and 16x16mm. Both patterns should be supported by contemporary 5 FPV drone frames. M3 screws are used in these motors’ mounting holes. Use screws whose thread length is 2 mm longer than the arm thickness; for instance, use 7 mm screws for 5 mm arms and 8 mm screws for 6 mm arms.

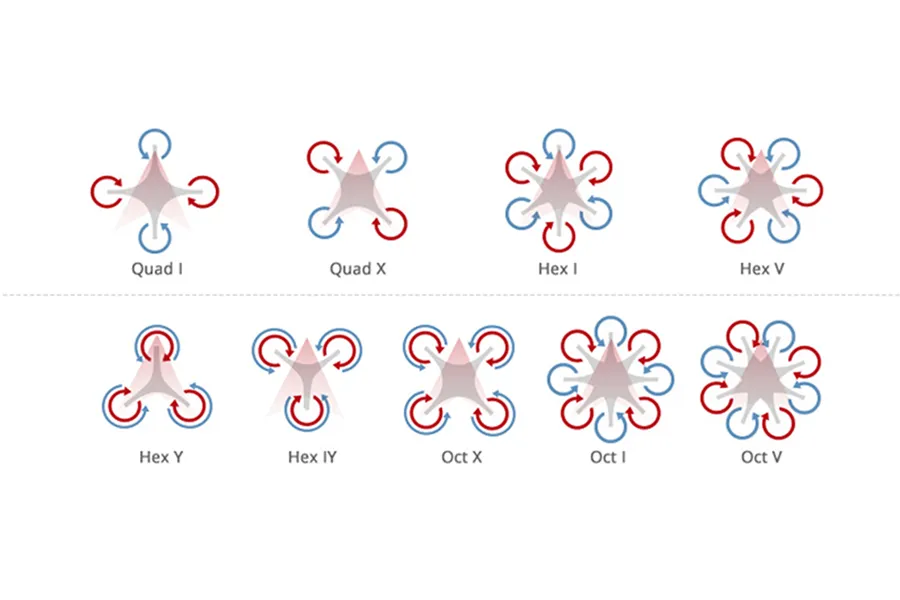

Motor Rotation Direction

If all drone motors are installed spinning in the same direction, the quadcopter will not respond correctly to control inputs, making stable flight nearly impossible. To achieve balanced thrust and smoother flight characteristics, motors must be paired in opposite directions: clockwise (CW) and counterclockwise (CCW).

For example, when building a quadcopter, two motors should spin clockwise and the other two counterclockwise. This counter-rotation balances torque and ensures the aircraft can yaw, pitch, and roll as intended.

What Factors Affect Real-World Motor Performance?

When choosing an FPV motor for your drone build, it’s important to consider more than just KV and size. Key performance factors such as torque, throttle response, motor heat, and vibration will directly affect how smooth, powerful, and efficient your quadcopter flies. Here’s a breakdown of what to look for:

Motor Torque

Torque is the force that allows the motor to spin the propeller and change RPM quickly. High-torque FPV brushless motors deliver faster throttle response and precise control, which is especially useful for freestyle tricks, sharp turns, or aggressive racing maneuvers. They can also handle larger or higher-pitch propellers, making them suitable for carrying payloads such as HD cameras.

On the other hand, higher torque usually comes with higher current draw, which may shorten flight time, strain batteries, and increase ESC load. For cinematic or long-range flying, many pilots prefer lower-torque motors to achieve stable, energy-efficient performance. When choosing between motors of similar size, the lighter option often provides a better balance of control, efficiency, and reliability.

Response Time

Motor response time refers to how quickly the motor reacts to throttle changes—critical for racing drones and acro flying. A motor with fast response enables crisp flips, quick recoveries, and precise stick inputs.

Response time is strongly linked to torque and also depends on your propeller weight, blade shape, and ESC tuning. Lighter props and low-latency ESCs help minimize delay and improve overall drone responsiveness.

Temperature

Heat management is crucial to motor efficiency and durability. Excessive heat can weaken the magnets inside a brushless motor, leading to power loss, demagnetization, or permanent damage.

Common causes of overheating include over-propping, full-throttle abuse, or poor airflow in the drone frame. Choosing motors with built-in cooling fins, vent holes, or low internal resistance helps reduce operating temperature. For FPV racers or pilots flying in hot environments, keeping motors cool extends both performance consistency and lifespan.

Vibration

Motor vibration can create tuning challenges, especially if it disrupts the flight controller’s gyro. Vibrations often come from poor motor balance, damaged propellers, or bent motor shafts. They can cause oscillations, increase electrical noise, and degrade FPV video quality, especially if your video transmitter is powered from the main battery.

To minimize vibration issues:

- Use well-balanced FPV motors

- Replace worn or chipped props

- Consider soft-mounting flight controllers

- Avoid low-quality motor bearings

Stable motors mean better flight performance, smoother footage, and easier PID tuning.

Comparing FPV Motors

Even after deciding on motor size and KV rating, there are still many options available. To choose the right FPV motor for your needs, consider the following factors:

Thrust

Thrust determines how much lift your quadcopter can generate. Higher thrust allows for faster speeds and more aggressive maneuvers, but usually requires more power, which can shorten flight time.

Current Consumption

Every motor draws current from the battery. Motors that consume too much current can cause overheating, shorten battery lifespan, or overload the ESC. Always ensure your motor and battery pairing stays within safe current limits.

Efficiency

Efficiency is the balance between thrust output and power consumption. A highly efficient motor delivers strong performance without draining the battery too quickly—crucial for both long-range flights and racing, where every second of flight time matters.

Weight and Rotational Inertia

Motor weight affects the overall thrust-to-weight ratio of the quadcopter, as well as its agility. Heavier motors increase rotational inertia, meaning flips, rolls, and other acrobatic maneuvers may feel slower or less responsive. For racing and freestyle, lighter motors are often preferred to improve responsiveness. For cinematic or endurance flights, slightly heavier motors may be acceptable if they provide smoother control and stability.ance or an area where you want your quadcopter to perform better at the expense of another!

More Tips on FPV Drone Motor Efficiency

The lighter your multi-rotor drone, the more efficient its performance will be. Striking the right balance between motor choice, battery selection, and overall weight is critical to achieving smooth and responsive flight. While lithium polymer (LiPo) batteries play an important role, efficiency is also strongly influenced by the motor you choose.

When selecting a motor, efficiency should be considered alongside KV rating and thrust output. A good way to understand this is by comparing it to riding a bicycle. In a lower gear, you can ride faster, but you also need to pedal more quickly and face greater resistance. As the terrain becomes steeper, pedaling gets harder, and eventually, no matter how hard you try, your speed decreases—this is the point where efficiency drops.

Brushless motors behave in a similar way. A motor with 70% efficiency converts 70% of electrical power into thrust while wasting 30% as heat. By contrast, a 90% efficient motor delivers much more usable power with minimal heat loss.

Using a less efficient motor has several downsides:

- Shorter flight times due to excess energy lost as heat.

- Reduced thrust at full throttle.

- Sluggish response and poor stability, since the motor takes longer to reach target RPM.

We hope this blog has helped you understand the parameters of quadcopter motors.

Here are the videos about the motor:

FAQs

Can I use 6S motors on a 4S battery?

Yes, but the drone will feel extremely underpowered. A 1750KV motor on 4S will only reach about 65% of the RPM of a native 4S setup. It is not recommended unless you are just practicing hovering.

Is high torque better than high speed?

For 5-inch freestyle drones, a balanced torque profile is the most stable option. High torque allows the motor to overcome “prop wash” (the turbulence created by the drone’s own air) much faster. Based on pilot feedback, motors with higher torque provide a “locked-in” feeling that makes tuning your PID controller much easier.

Why does FPV motor temperature matter?

If your FPV motors are too hot to touch (over 65°C/150°F) after a flight, your setup is inefficient or poorly tuned. Excessive heat causes “demagnetization,” which permanently kills your motor’s performance. MEPSKING motors like the SZ2207 feature an open-base design to maximize airflow and keep temperatures stable even during back-to-back racing heats.

Is a higher KV motor always better for FPV racing?

The short answer is no; higher KV is not always better. While a high KV motor spins faster and provides explosive acceleration, it also draws significantly more current and can quickly overheat your ESC or sag your battery. For 6S racing in 2026, the safest choice is a mid-range KV (1750KV–1950KV) which offers the best balance of top-end speed and manageable power consumption.