If your FPV motors are getting hot, it’s usually caused by improper tuning, prop mismatch, over-throttling, or insufficient cooling. To fix it, check your PID tune, motor timing, prop size, and ESC settings. Always ensure good airflow and avoid flying on low-efficiency props or overly aggressive rates.

Why is it Important to Cool FPV Motor?

After a vigorous flight, it’s common for FPV motor to get warm, but how hot is too hot? Pinching the engine by the bell with your fingertips—ideally immediately after landing—is a simple technique to find out. It’s acceptable if you can comfortably hold your fingers there for more than ten seconds. It may indicate overheating if it gets too hot to handle.

- When fpv motors overheat, the winding’s coating may melt, creating internal electrical shorts that will emit smoke and cause irreversible damage to the fpv motor.

- Overheating motors can eventually affect performance since the magnets lose their magnetic strength; Certain magnet types may be more heat resistant than others.

- Heat wastes more energy, which reduces flying duration.

How FPV Motors Work?

FPV (First-Person View) motors are a crucial component of an FPV drone, responsible for converting electrical energy from the battery into mechanical energy that spins the propellers, allowing the drone to fly. Understanding how these motors work can help diagnose and prevent issues like overheating.

- Electromagnetic Induction: When electrical current flows through the stator’s windings, it generates a magnetic field. The arrangement of the windings and the timing of the current flow create a rotating magnetic field.

- Interaction with the Rotor: The magnetic field interacts with the permanent magnets in the rotor, causing it to spin. The rotor’s rotation drives the motor shaft, which in turn spins the propeller.

- Speed Control: The motor’s speed is controlled by an Electronic Speed Controller (ESC), which adjusts the amount of current and the timing of the magnetic field in the stator. The ESC is governed by input from the drone’s flight controller, responding to the pilot’s commands.

FPV motors work by converting electrical energy into mechanical energy through electromagnetic induction. The interaction between the stator’s magnetic field and the rotor’s magnets spins the motor and propeller, enabling flight. Understanding these components and how they interact is key to troubleshooting and optimizing your FPV drone’s performance.

Overheating often occurs when FPV motors are overloaded or paired with incompatible props. You can test our FPV motors for free through the MEPSKING Vine Voice program, share your genuine experience, and help us refine our product quality.

What May Cause FPV Motors Getting Hot?

It will heat up your FPV motor after some high-speed flying. You should fly at a slower speed to accurately assess the problem; 40% to 70% throttle is a decent starting point, and a few occasional flips and rolls are acceptable.

Propellers Too Large or Too Aggressive

Main cause: Oversized or high-pitch props make your motors work harder to spin them. This increases current draw and creates excessive heat.

Example:

Using 5.1×5.1×3 props on 2306 motors will cause way more load than 5×4.3×3 props.

Motor KV Too High for Your Battery Voltage

High KV = High RPM = High Current = More Heat.

If you’re running 2500KV motors on a 6S battery, you’re likely pushing them past their safe operating range.

Suggested KV ranges:

- 4S builds → 2300–2600KV

- 6S builds → 1700–1900KV

If you’re looking for high-performance yet cool-running motors, the MEPS NEON 2306 or MEPS SZ2207 motors are excellent examples.

They feature:

- High-temperature-resistant windings

- Efficient stator design for lower internal resistance

- Lightweight titanium shafts for smooth rotation

Soft-Mounting FC

You really ought to soft-mount the FC if you’re not already! You don’t have to bother with soft mounting the fpv motors as long as you are correctly soft attaching the FC.High power fpv motors can produce high frequency mechanical noise that can cause vibrations and oscillations in the flight controller. We can prevent vibrations from reaching our flight controller’s gyro sensor by using soft mounting.

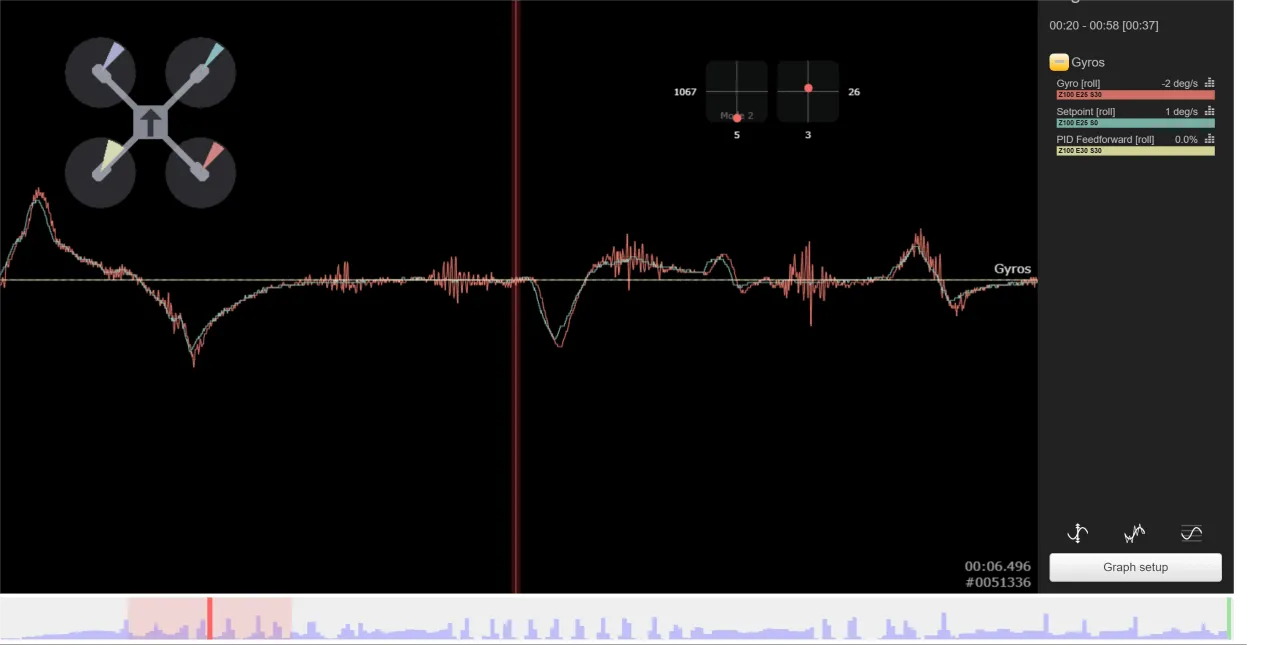

Overly Aggressive PID or Filter Settings

Higher D gain will basically push the fpv motors harder, and when they are unable to handle the rapid change of RPM, it will cause them to stutter, making your quad to oscillate, and eventually leads to overheat. The oscillation will go back into the gyro and can make the problem worse.

An overactive D term is frequently reason why fpv motors get heated. The D term balances out the little oscillations you detect on an aggressive P term since it dampens noise that the gyro receives. Nevertheless, a high D term can result in overheated motors if the configuration is extremely noisy or for a variety of other reasons.

Symptoms:

- Motors hot even after short hover

- “Hot motors” warning in OSD

- D-term oscillation visible in blackbox log

The first thing you may do is soft mount your flight controller using O rings or rubber bobbins if you choose not to tamper with your PIDs. In addition to having cooler fpv motors, your quadcopter should fly smoother overall as a result of this helping to lessen vibrations traveling to the gyro.

Try lowering the D term if you’ve already soft mounted to see if it makes a difference. Again, only if your fpv motors are getting too hot to handle should you be concerned about this. You can live with them and your quad should not experience any problems if they are heated but manageable.

Mechanical Problem

Perhaps there is a mistake in the build process.

- Verify that the screws on the fpv motors and frame are tight.

- Are all of the arms erect and inflexible?

- FC is firmly fixed in place (standoffs in the stack and nylon screws).

Bearings, Magnets, or Shaft Damage:

A damaged motor will create friction or magnetic imbalance, making it heat up fast.

How to diagnose:

- Spin the motor by hand — it should feel smooth and silent.

- Any grinding, clicking, or resistance means a bad bearing or shifted magnet.

ESC Settings and Timing Mismatch

Incorrect ESC configuration can easily cause FPV hot motors.

Check in BLHeliSuite:

- Motor Timing: Set to Medium or Medium-High (avoid “Extreme”).

- PWM Frequency: 24–48kHz is stable for most motors.

- Current Limit: Make sure it matches your motor’s amp rating.

Tip: Higher PWM (like 96kHz) can make motors smoother but may slightly increase temperature — find the sweet spot for your setup.

Unbalanced Weight Distribution

An uneven weight distribution could be the reason for two of the fpv motors being hotter than the others. Two of the motors on your quad will have to work harder and heat up more if it is front heavy or tail heavy. To ensure optimal performance, position the COG precisely in the center.

Weather Condition

Consider the outside temperature; on a hot day, it will take longer for your fpv motors to cool down. Flying under the sun will have an even greater impact on black motors. If so, give it another go in the evening or in the shadow.

- High ambient temperature: Hot summer flights increase baseline heat.

- Continuous full throttle: Freestyle punch-outs or racing laps keep motors near max current.

- Poor airflow: Tight frames or ducts trap heat (especially in cinewhoops).

How to Fix the Issue of FPV Motor Getting Hot?

Change the Propellers

Changing the props is the initial step in the debugging process. How come? thus they can be replaced most easily and at the lowest cost. Start there if you’ve had good luck with a specific kind of prop in the past. Take their place with fresh ones and retest. This is sometimes as simple as solving the problem.

- Downsize your props (smaller diameter or lower pitch).

- Try switching from tri-blade to bi-blade for less resistance.

- Check prop balance — bent or chipped props increase vibration and load.

Change Motor KV

Match motor KV with battery voltage. If you want more speed, use a lower KV motor with a slightly higher pitch prop instead of pushing high KV too far.

Suggested KV ranges:

- 4S builds → 2300–2600KV

- 6S builds → 1700–1900KV

PID and Filter Tuning in Betaflight

In Betaflight, PID and filter tuning can be a maze. You should return to the original PID and filter settings in Betaflight if you are experiencing hot motors after making changes to them.

In order to prevent oscillations and overheated motors, Betaflight’s default settings are well-known for being cautious and generally functioning well on a variety of models. You can begin more aggressive tuning, one setting at a time, when you’ve confirmed that you’re no longer experiencing overheated motors. Crucial elements are:

- D Term: Is it too high? (Why would oscillations result from a high D gain?)

- Did you over-reduce the filtering?

Fixes:

- Lower D-term by 10–15%

- Increase D-term filtering slightly

- Check blackbox for vibration spikes

- Run Motor Output Limit or Throttle Limit if necessary

If the fpv motors continue to run hot even with the PID and filter settings set to default, there may be a mechanical issue, such as bad components or low build quality.

Bearings, Magnets, or Shaft Damage

- Clean or replace the bearings.

- If the bell is cracked or magnets are chipped, replace the motor.

- Make sure screws are not rubbing against the stator windings.

Desyncing Motors

Desyncing may result from a drone motor overheating. When a fpv motor stalls or stops spinning at the same rate as the other motors, this happens. Even when the motor signal reaches its peak, this could still occur. Your drone may operate erratically or fall out of the sky if it is out of sync.

In the event that this occurs, closely observe the drone’s failing side. In this manner, based on the drone’s condition following the failure, you will be able to determine which motor is at blame and take appropriate action.

If you are using BLHeli or Betaflight, you should adjust their settings to resolve this issue or lessen the likelihood that it may arise in the future. Installing the most recent version of each program is the most effective approach to implement the changes. Although these settings may not be the best for performance, they are the most effective.

Changing the drone motor out for a new one is an additional option. This is more appropriate in the event that your drone crashes and certain internal fpv motor parts were damaged. If a damaged motor is left in place, it could jeopardize other motors and increase your total losses.

How to Diagnose Hot Motors?

| Checkpoint | What to Do | Normal Result | Warning Sign |

|---|---|---|---|

| Spin by hand | Turn prop slowly | Smooth & free | Grinding or resistance |

| After short hover | Touch test | Warm (below 60°C) | Too hot to touch |

| OSD current draw | Monitor amps | Steady & moderate | Sudden high spikes |

| Blackbox log | Check D-term | Clean wave | High-frequency oscillation |

| ESC config | Review timing/PWM | Medium timing | Extreme/high values |