What Are Heavy Lift Drone Motors?

Heavy lift drone motors are high-power brushless motors specifically designed for drones that need to carry large payloads — typically used in models with total takeoff weights ranging from 2 kg to 100 kg or more. Compared with regular FPV drone or hobby drone motors, huge drone motors feature the following characteristics:

- Larger stators (130mm or larger) that generate more torque.

- Low KV → High Torque: Large propellers require greater torque to start and maintain rotational speed. Low KV motors offer a higher torque-to-current ratio, making them suitable for large-diameter propellers.

- Exceptional thrust — some industrial motors can exceed 60–100 kgf per motor at peak power.

- Enhanced heat dissipation and durable bearings for continuous heavy-load operation.

These large drone motors are widely used in industrial drones, agricultural UAVs, cinematic lifters (cinelifters), and long-range FPV rigs that demand stable thrust and long endurance.

Key Features of Heavy Lift Drone Motors

Here are the key features of heavy drone lift motors:

| Feature | Description |

| High Torque Design | Heavy lift drone motors use larger stators (typically 130mm or larger), which generate more torque for better thrust and lifting capacity. |

| Low KV Rating | With KV values between 30–800KV, these motors deliver smooth and efficient rotation for large propellers, ensuring stable flight under heavy load.If the load is lighter, the motor’s KV rating will be higher. |

| Exceptional Thrust | Some models can produce 60 kgf or more of thrust per motor, allowing drones to carry cameras, sensors, or agricultural equipment effortlessly. |

| Efficient Cooling System | Built with enhanced heat dissipation and durable bearings, they can handle continuous, long-duration operations without overheating. |

| High Durability | Designed with aerospace-grade materials and advanced winding technology to withstand demanding industrial environments. |

| Precision Control | Paired with reliable ESCs and optimized firmware, these motors offer smooth throttle response for accurate and stable flight control. |

Applications of Heavy Lift Drone Motors

Agricultural Drones

In agricultural UAVs, heavy lift motors enable drones to carry liquid payloads (sprayers, tanks) or seed dispensers over wide fields. These flights demand sustained thrust, good efficiency, and resistance to corrosive environments.

Typical payloads: drones that carry 5 – 20 kg of liquid or chemical spray tanks. For example, a crop‐spraying octocopter may carry ~10 kg payload.

Motor key attributes:

- Low KV rating (approximately 100-200KV) enables large propellers to rotate slowly and efficiently under load.

- High thrust rating (8-18 kg or higher) supports takeoff with heavy fuel tanks and maintains altitude. For example, agricultural drones utilize motors with approximately 18.2 kilograms of thrust.

- Corrosion-resistant construction for “all-weather” environments (dustproof, splashproof, moisture-resistant).

Industrial/Logistics/Mapping Drones

Industrial heavy-lift drones handle surveying, mapping sensor, cargo transport, or infrastructure inspection tasks. Their motors must support large frames, carry heavier payloads, and extend flight duration.

Payload Range: Most industrial drones have takeoff weights between 5–80 kg, depending on the mission type — mapping drones are lighter, while logistics and agriculture drones can exceed 50 kg.

Essential Motor Characteristics:

- Typically featuring low KV motors (60–200KV) paired with large 20–40 inch propellers, ensuring efficient lift and high torque for heavy payloads.

- Delivers high sustained thrust with exceptional thermal stability.

- Motors are optimized for high-voltage power systems (6S–14S, up to 24S in special applications) to maximize efficiency and reduce current draw.

Aerial Cinematography

In professional aerial filmmaking, smoothness and vibration-free movement are just as critical as lifting capacity. Heavy-lift drone motors deliver the torque and precision required to carry large cinema cameras, gimbals, and high-capacity Li-ion battery packs while maintaining stable flight dynamics.

Payload Capacity: Typically supports 3–15 kg of equipment, depending on the camera and stabilization setup.

Motor Specifications:

- Medium-to-low KV motors (200–400 KV) combined with 15–26 inch carbon fiber propellers for efficient, responsive lift.

- High mechanical precision and ultra-low vibration to ensure perfectly stable footage.

- Premium bearings and advanced thermal design for long-duration, professional film operations.

FPV Drones (Cinelifter & Long Range)

While most FPV drones are renowned for their agility and freestyle flight performance, the FPV community has recently begun adopting heavy lift drone motors to expand into cinematographic aerial photography, long-range flights, and professional aerial production. These powerful motors enable pilots to carry high-end cameras, advanced HD transmitters, or lithium-ion battery packs, achieving longer flight ranges and more stable flight.

Unlike traditional lightweight FPV motors, heavy lift FPV motors prioritize torque output, control stability, and thermal management over raw speed. This makes them ideal for cinema-grade FPV drones, long-endurance cruisers, and professional filming or heavy-load custom platforms.

FPV drone flight includes: Long-Range, Cinelifter, X-Class.

| Build Type | Typical Motor Class | KV Range | Propeller | Voltage |

| 6″–8″ Cinelifter | 2806.5 / 2812 | 900–1200 KV | 6″–8″ | 6S |

| 10″–12″ Long-Range | 3115 / 3510 | 650–900 KV | 10″–12″ | 6S–8S |

| 13″–16″ Cine Rig | 4220 / 5315 | 250–350 KV | 13″–18″ | 12S |

Pilots interested in testing MEPS or T‑Hobby heavy lift drone motors can explore the MEPSKING Vine Voice program, where you can try motors and share your experiences to help refine product performance.

Key Features of Heavy Lift Motors for FPV Drones(Long-Range & Cinelifter)

| Feature | Description |

| Balanced Power & Efficiency | Designed to maintain steady thrust while conserving battery life during long, smooth cinematic flights. |

| KV Rating | Ideal for carrying heavier payloads with large propellers, providing smooth throttle response and precise control. |

| Adjustable KV for Different Loads | Generally, the heavier the payload, the lower the KV. Conversely, if the drone carries a lighter load, a higher KV motor offers better agility and quicker throttle response. |

| High Torque Output | Delivers consistent lift and stability even when equipped with cameras or heavy FPV systems. |

| Thermal Stability | Built with high-temperature-resistant windings and durable bearings to prevent overheating during extended flights. |

| Optimized for Cinematic Builds | Delivers smooth, vibration-free footage even when carrying extra payloads or flying in windy conditions. |

How to Choose the Right Heavy Lift Drone Motor?

Selecting the right heavy lift drone motor is one of the most critical steps in building a reliable, efficient, and high-performing aircraft. The choice directly affects lift capacity, stability, energy efficiency, and long-term durability. Whether you’re designing a drone for aerial cinematography, agriculture, or industrial use, the same engineering principles apply.

Determine Total Drone Weight and Thrust-to-Weight Ratio

Start by estimating your drone’s total takeoff weight — including the frame, battery, flight controller, payload, and accessories. Then, add a 10–20% buffer to account for future upgrades or equipment changes.

The next key factor is the thrust-to-weight ratio. For stable and efficient performance, follow these benchmarks:

| Drone Type | Recommended Thrust-to-Weight Ratio | Example Use | Performance Goal |

| Standard Multirotor | 2:1 | Hobby or small mapping drones | Minimum lift capability |

| Professional / Aerial Photography | 3:1 | Cine drones, mapping | Smooth control under load |

| Industrial / Agricultural Heavy-Lift | 3.5–4:1 | Spraying, cargo, LiDAR | Extra thrust for payload and stability |

| FPV Heavy-Lift | 4–6:1 | Long-range or cinematic FPV | Agility and acceleration with heavy camera gear |

A minimum ratio of 3:1 ensures safe takeoff and stable hovering even with variable payloads. For heavy-lift FPV drones, a 4:1 ratio or higher is often preferred to maintain responsiveness during dynamic maneuvers.

Match Motor KV Rating to Propeller Size and Payload

A motor’s KV rating defines how many revolutions per minute (RPM) it spins per volt applied without load.

Here’s the general matching guideline:

| Effective Payload | Typical Battery | Recommended KV (rpm/V) | Recommended Propeller Diameter (inch) | Notes |

| Up to 4 kg | 4S–6S | 800–1500 KV | 7″–8″ | Suitable for micro drones, lightweight FPV drones, small cameras, and short-arm multirotors |

| Small Payload / Lightweight Aerial Photography | 4S–6S | 450–800 KV | 9″–12″ | Suitable for small cameras, compact lenses, and short-arm multirotors |

| Medium Payload / Standard Aerial Photography | 6S–8S | 220–450 KV | 12″–15″ | Common for mid-size aerial platforms with larger arms |

| Large Payload / Professional Aerial Photography | 6S–12S | 100–300 KV or lower | 15″–18″ (up to 20″) | Supports heavy cameras, gimbals, and extended flight batteries |

Pro Tip: The heavier the payload, the lower the KV you need — allowing the motor to swing larger props at lower RPM for greater efficiency.

If the payload is lighter, you can safely choose a higher KV motor to gain responsiveness and speed.

Frame Size and Propeller Clearance

Your frame size determines the maximum propeller diameter. A good rule of thumb: the propeller diameter should be one-third of the frame size.

For example, a 900 mm frame typically supports 30-inch props efficiently.

Adequate prop clearance ensures optimal airflow and minimizes vibration, which directly affects flight stability and motor life.

Understand Torque, Efficiency, and Cooling

Torque depends on stator volume, magnet strength, and coil quality.

Larger stators generate more torque, perfect for heavy drones, but also increase weight.

For industrial or agricultural drones that fly long missions, wide stator motors are ideal — they stay cooler under load and maintain consistent RPM.

Look for these performance markers:

- Motor efficiency above 85%

- High-temperature-rated copper windings

- Oversized bearings for durability

- Ventilated or IP44-protected motor housing

Efficient motors not only extend flight time but also protect ESCs and batteries from overheating.

Propeller Matching for Maximum Efficiency

Proper propeller-to-motor matching is essential to avoid overloading the motor or wasting energy.

- Low KV + large propellers = high torque and stability (ideal for aerial photography, agriculture, mapping).

- High KV + small propellers = high RPM and agility (ideal for FPV freestyle or racing).

For heavy lift drones:

- Use two- or three-blade carbon fiber props for a balance between efficiency and lift.

- Maintain motor efficiency above 83% by choosing a prop within the motor’s optimal thrust range.

- Dynamic testing with a thrust bench helps verify whether the motor-prop combo achieves your target thrust-to-weight ratio without overloading your ESC.

ESC and Power Compatibility

Choose an ESC (Electronic Speed Controller) rated 20–30% higher than your motor’s maximum current draw.

For instance, if your motor draws 40A at full throttle, pair it with a 50A ESC.

This buffer prevents overheating and extends the system’s lifespan.

Also, ensure your ESC supports the voltage range of your battery (e.g., 6S, 8S, or 12S systems for heavy-lift).

FPV Drone Heavy-Lift Motors: A Special Case

In FPV, “heavy-lift” has a different meaning — it refers to carrying extra gear such as action cameras, GoPro batteries, or even RED KOMODO cinema setups.

FPV heavy-lift drones prioritize agility with payload rather than pure endurance.

They use:

- 8–15 inch frames

- Motors in the 2806.5–5315 class

- KV between 300–1500 for 6S setups

- Thrust range of 3–6 kg per motor

Best Heavy Lift Drone Motors in 2025 (Tested & Reviewed)

T-MOTOR U15XL KV38 — Industrial Power for True Heavy Lift Drones

Specs:

- Max Thrust: 100 kgf

- Power: 23 kW

- Voltage: 100 V

- Weight: 4.4 kg

- Propeller: 52×20-inch carbon fiber

The T-MOTOR U15XL KV38 is built for serious heavy-lift operations, delivering up to 100 kg of thrust with a 23 kW power output. Designed for large multirotor and industrial UAVs, it offers outstanding efficiency and torque stability under continuous load.

Its aerospace-grade construction and robust 300A ESC compatibility make it ideal for missions like cargo delivery, mapping, and aerial logistics. Paired with a lightweight 52×20-inch carbon fiber prop, the U15XL KV38 delivers smooth, vibration-free performance and consistent lift power.

Compact, durable, and incredibly strong, it’s one of the most reliable motors in 2025 for drone platforms carrying 70–100 kg payloads.

T-Motor U15L KV43

Specs:

- Rated Model: U-Series Heavy-Lift UAV Motor — KV 43.

- Weight (incl. cables): ~ 3,600 g.

- Dimensions: Φ151.5 × 86 mm.

- Internal resistance: 20 mΩ.

- Rated voltage: up to 24 S LiPo (which is ~100 V).

- Peak current (120 s): ~135 A.

- RobotShop

- Max thrust (documented): ~60 kg (≈132 lb) class with proper prop/voltage setup.

The motor spins large props effortlessly, so when I mounted a full rig (camera + gimbal + big battery), the U15L still delivered predictable throttle feel and solid climb.

It handled thermal stress well. After multiple 6-7 minute flights with payloads, temps stayed acceptable — no panic shutdowns or overheating signs.

Build-quality shows: huge bearings, massive 25 mm shaft, and a motor housing designed for large-scale multirotors. Feels premium and rugged.

If you’re building for tasks like aerial cinematography, cargo delivery, or industrial inspection where you need serious lift (50 kg+ class payloads), this motor hits the mark. For smaller drones, it might be overkill — but for “big bird” missions, it’s spot-on.

Best Heavy Lift Motors for FPV Drones

| Motor | Approx KV / Range | Intended Prop Size / Frame | Notable Specs / Thrust | Why It Stands Out |

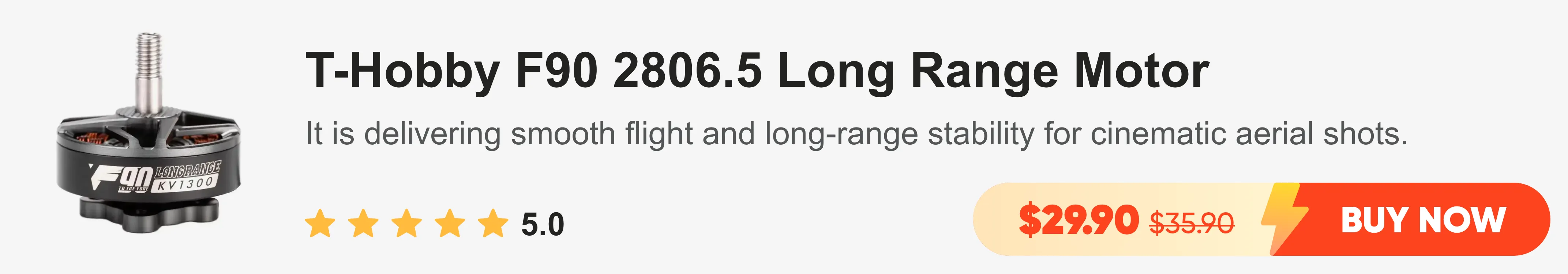

| T-Hobby F90 2806.5 | 1300 / 1500 / 1950 KV | 6″–8″ props, 7″–8″ long-range rigs | Weight ~46.6 g, Max Power ~1302W (60s) | Excellent for 7–8″ long-range FPV builds carrying extra battery/camera. |

| MEPS NEON 2812 | 900 KV / 1150 KV | 8″ props, cinematic 3–4″ imagine but scaled up | Thrust ~3829 g (with 8″ props) | Strong performer for 8″-class FPV rigs with heavier gear—balanced between lift and agility. |

| MEPS NEON 3115 | ~1050 KV (per listing) | 8″–12″ props | Built for larger frames, long-range & cinematic FPV | Good option when you scale up beyond typical 6–8″ FPV builds. |

| T-Hobby Cine99 4220 | 350 KV (as stated) | 13″–18″ props, large-frame cine drones | IP45 protection, built for professional payloads | Bridges FPV with true lightweight cine rigs—large prop driven for smooth footage. |

| T-Hobby V5315 | 300 KV | “13-inch X4 or X8 cinematic drones” (so large props) | >6.5 kg max thrust, 3–6 kg continuous under heavy load | Maximum scale FPV / cine motor for ultra-heavy rigs. |

Setup Tips for Building a Heavy Lift FPV Drone

- Match motor KV to prop size and voltage for best efficiency.

- Use ESCs with at least 20% headroom above max amp draw.

- Distribute weight evenly to avoid stressing motors.

- Use 6S–8S LiPo batteries for maximum thrust and efficiency.

- Calibrate all motors carefully for balanced thrust.

- Balance propeller pitch and size to avoid overloading motors.

- Test flights at low throttle first to ensure stability under payload.

- For FPV or aerial filming, tune PID settings after mounting payloads to stabilize flight dynamics.

FAQs about Heavy Lift Drone Motors

How much weight can a drone motor lift?

It depends on the drone’s overall setup — motor size, propeller diameter, battery voltage, and total thrust output.

Standard large drones can typically lift 5–30 kg (11–66 lbs), while true heavy-lift platforms start around 20–25 kg (44–55 lbs) and can reach 70 kg (154 lbs) or more. In industrial designs using multi-motor configurations, total lift capacity can exceed 200 kg (440 lbs).

What frame size works best for heavy-lift drones?

Frame size directly limits propeller diameter. A good rule:

The maximum propeller diameter ≈ one-third of the frame’s diagonal size.

For example, a 900 mm frame typically supports 30-inch props, while a 550 mm frame works well with 17–18 inch props. Larger frames improve stability and vibration isolation during heavy-load flights.

How much thrust should each motor produce?

Each motor should deliver enough thrust to lift at least one-quarter of the total drone weight, plus a margin.

For a 20 kg drone with four motors, each motor should generate at least 10 kg of thrust (2× the per-motor weight share).

High-end setups often target 12–15 kg of thrust per motor for performance and safety redundancy.