Introduction

What is a Capacitor for Drone?

One of the most prevalent parts of an electronic system is a capacitor. Almost single electronic component used in our FPV drones, as well as practically all other electronic equipment, has many capacitors. Although capacitors exist in a wide variety of sizes and shapes, their capacitance to store charge generally increases with size. The most popular application of a capacitor is supply voltage smoothing. This type of application for a capacitor is known as decoupling.

Similar to a small battery, a capacitor for drone may absorb and release electrical energy rapidly. It stores electric charge in an electric field between two conducting plates. To equal out voltage variations and shield other components from harm, the capacitor absorbs spikes in voltage and releases its stored energy when there is a drop in voltage.

The Benefits of Extra Capacitors in FPV Drones

In essence, the FETs in our ESC are switches. To power the motors, they rapidly switch on and off tens of thousands of times per second, which can produce a great deal of noise and electrical spikes. The issue gets worse as technology develops and makes stronger motors, ESCs, and greater battery voltages possible. It can make the difference between an amazing first-person perspective drone and one that is entirely unflyable, therefore the noise problem is really important.

While the motors spin up or while the drone is making fast movements, drone capacitors can aid to lessen electrical noise and voltage spikes. Capacitors can also aid in lowering the quantity of interference produced by the power supply, which can enhance the quality of the analog video stream captured by the drone’s camera. More noise is produced by larger motors and high-current ESCs, necessitating larger or more capacitors.

Surface mount capacitors are used for filtering in ESC and FC, although they are typically insufficient because of the limited physical area. In conclusion, increasing the number of capacitors in our FPV drone can offer the following advantages:

- ESC/motor-generated electrical noise is filtered to lessen interference with ESC, radio, and video signals.

- Enhancing flight performance by gyro signal “cleaning up”.

- Safeguarding devices against harmful voltage spikes. By acting as a buffer, capacitors stop any extra energy from getting to the sensitive parts.

- Having enough capacitors for drone at the input power can assist minimize video noise in your FPV feed if you fly analog.

Do You Need To Add Capacitor for Drone?

The ESC will work OK without extra drone capacitors, but you run the danger of the ESC deteriorating over time because the onboard capacitors must manage spikes, which raises their temperature and reduces their longevity. Long battery leads won’t be able to handle the extra noise because of the low onboard capacitance.

The first thing you should usually attempt if you have a noisy quad (lots of oscillations, difficult to adjust PID and filters) or noisy video feed is to add capacitors. Here’s how to determine if you need a capacitor for drone because it’s too noisy.

- Check to see if there are any oscillations coming from the motors that PID cannot detect.

- Look for any hot motors.

- Another indication of electrical noise in the power system is noise in your video feed.

- In extreme situations, noise-corrupted ESC signals might result in ESC/motor desync and the “roll of death.”

What Type of Capacitor do You Need for an FPV Drone?

Electrolytic Capacitors

The most common capacitors used in FPV drone are Electrolytic capacitors.

Typically, a capacitor is made up of two plates that are spaced apart by a non-conductive dielectric substance. An electrolyte is added to an electrolytic capacitor in order to significantly improve capacitance. It’s not strictly necessary to utilize an electrolytic capacitor. However, it’s unlikely that you will locate a sufficiently tiny, sufficiently large value, and enough large maximum voltage capacitor that is not electrolytic. Using an electrolytic capacitor has a few considerations but no inherent drawbacks.

- Electrolytic capacitors are polarized, in contrast to conventional capacitors. Verify the proper connection between the positive and negative terminals.

- Because the electrolyte will eventually dry out, electrolytic capacitors have a shorter lifespan than ordinary capacitors. However, FPV drone aficionados won’t likely have any problems with it because this won’t happen very often for several decades!

Capacitance Value

The capacitance of each capacitor is measured in Farads. The value merely indicates the amount of charge that the capacitor is capable of storing. A farad is a comparatively large charge. Capacitors are therefore far more frequently measured in milifarads, microfarads, or even lower units! Since farads are represented by the letter F, you can write milifarads as mF and microfarads as uF.

- 1 F = 1000 mF = 1000,000 uF

The ideal capacitance value for a particular application can be determined. That is typically not required, though, when selecting a decoupling capacitor. All we have to do is select a capacitance number that is likely a little higher than what we actually need. With the exception of a very slight weight gain or additional expense, having a little too much capacitance has no detrimental impacts.

Recommendations for capacitance values selected for FPV drones:

- For 3 inch sized drones and under: Use a 220–470 uF capacitor, or as big as your setup will allow.

- For 5 inch and 6 inch: For 4-in-1 ESCs, use a 1000uF; for individual ESCs, use 220uF to 270uF.

- For 7 inch: For bigger motors (28XX or more) and/or where space is available, use two 1000uF capacitors, or one 1000uF capacitor.

Capacitance Voltage

A capacitor’s maximum voltage tolerance must be taken into account in addition to the actual amount of charge it can hold. The capacitance and maximum voltage have an impact on the capacitor’s physical dimensions. Larger capacitors are typically able to tolerate higher voltages. As a result, we need to select a capacitor for drone with a maximum voltage rating that is sufficient without going overboard and getting an excessively large capacitor. Your battery voltage has a direct bearing on the maximum voltage you should select.

In every situation, confirm that the capacitor’s voltage rating is greater than the system voltage. Here’s a recommended chart for maximum capacitor voltages based on various LiPo battery sizes:

| LiPo Cell Count | Nominal Voltage | Full Charge Voltage | Recommended Capacitor Voltage |

| 2S | 7.4V | 8.4V | 16V |

| 3S | 11.1V | 12.6V | 25V |

| 4S | 14.8V | 16.8V | 35V |

| 5S | 18.5V | 21.0V | 35V or 50V |

| 6S | 22.2V | 25.2V | 50V |

| 8S | 29.6V | 33.6V | 63V |

| 12S | 44.4V | 50.4V | 100V |

Low ESR Capacitors

The ESR value is the last factor we need to take into account when selecting a capacitor for drones. The acronym for equivalent series resistance is ESR. The internal resistance (ESR) of a component is its value. It essentially explains the amount of energy that is lost within the part. Higher ESR may hinder the capacitors’ capacity to smooth the power supply in our decoupling application. To put it briefly, we are looking for a drone capacitor with the lowest feasible ESR value.

Capacitor Size Chart

The size of the frame affects the motors and ESCs that are employed, which in turn affects the size of the capacitor:

| Frame Size | Common Battery Voltage | Typical ESC Rating | Recommended Capacitor |

| 2-3 inch (Micro) | 2S-4S | 10-20A | 220µF – 330µF 25V |

| 4-inch | 4S-6S | 20-35A | 330µF – 470µF 35V |

| 5-inch (Freestyle/Racing) | 4S-6S | 30-50A | 470µF – 1000µF 35V-50V |

| 6-7 inch (Long Range) | 6S | 30-60A | 1000µF – 2200µF 50V |

| X-Class / CineLifters | 6S-12S | 60A+ | 2200µF+ (Multiple capacitors in parallel) |

Select a capacitor with a voltage rating that is at least 20% more than the maximum battery voltage.

- Use a 25V or 35V capacitor for 4S (16.8V maximum).

- Use a 35V or 50V capacitor for 6S (25.2V maximum).

- 8S or above (33.6V maximum): Make use of 63V or greater.

How to Install a Capacitor on FPV Drone?

What is the Best Place to Install a Capacitor on FPV Drone?

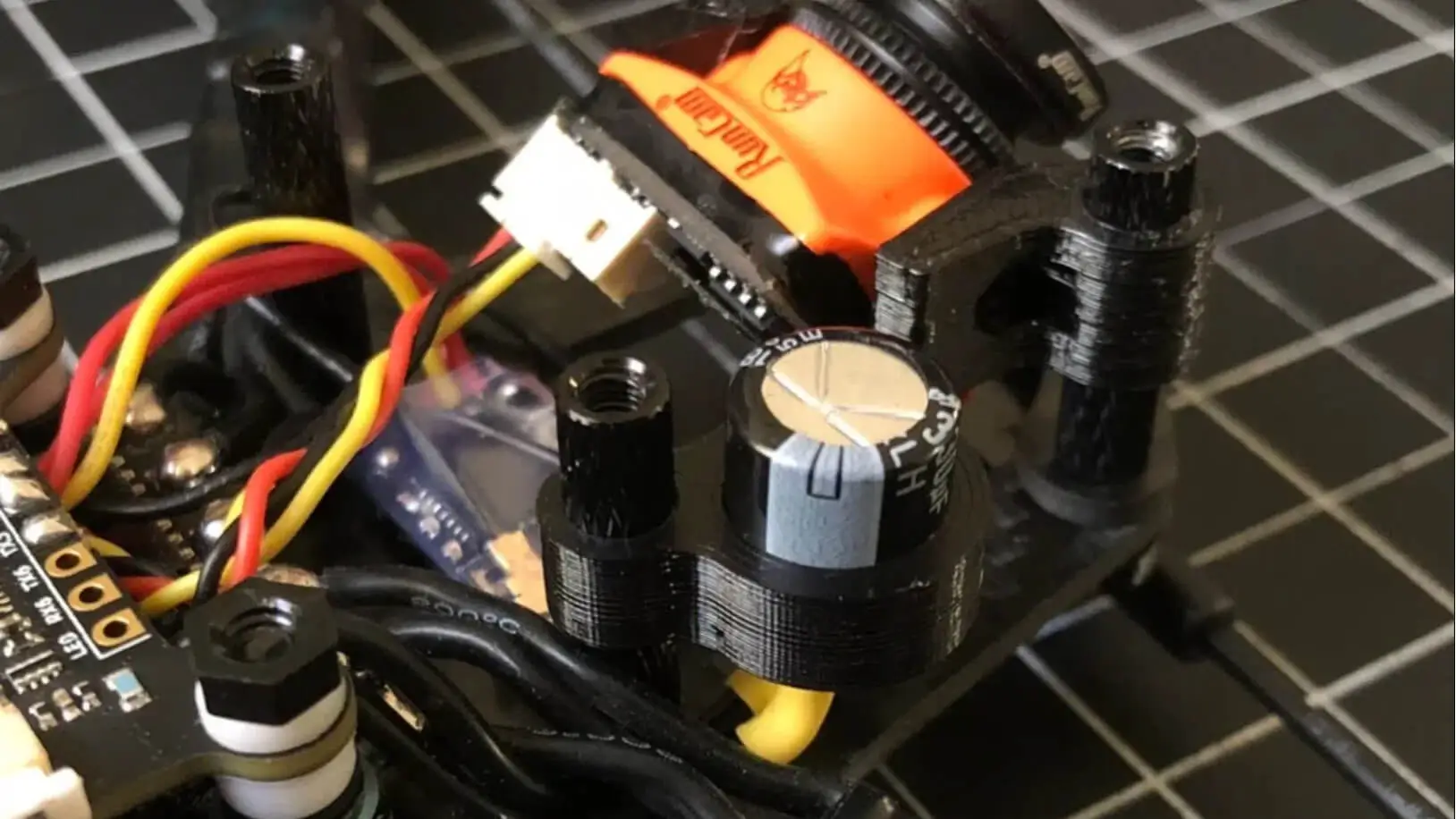

FPV drone capacitors must usually be added to the power supply, either directly onto the power pads of the ESCs or across the power lines. The basic concept is to enhance the usefulness of the drone capacitor by connecting it as electrically close to the MOSFETs in the ESC as possible. That typically refers to the power solder pads for 4in1 ESCs.

The ESC is often a single board that sits in the flying stack and powers all four motors in current models. The flight controller and ESCs are combined onto one board if you have an AIO. The battery connectors and the ESCs will be on the same board in both scenarios. To solder your capacitor, just solder it as close to the battery terminals as you can. Moreover, a lot of ESCs feature pads made expressly for mounting capacitors for drone. Since these pads are frequently located quite close to the battery terminals, it is acceptable to utilize them in their place. If you are utilizing different ESCs for every motor, you need to connect a capacitor to each ESC’s power terminal.

The Solution on the Mismatch Between Capacitor and FPV Drone

If there isn’t enough space, you can reduce the cap’s legs, solder some flexible silicone wires for an extension, and then move the cap to a different location inside the frame. To reduce resistance, however, make sure the wires are as short as possible and utilize thicker wires (for example, 20AWG or even 18AWG is a suitable choice for 6S 5).

FAQs

Why Should You Not Let Capacitors Touch Drone Frame?

Letting capacitors touch the drone frame can lead to several issues:

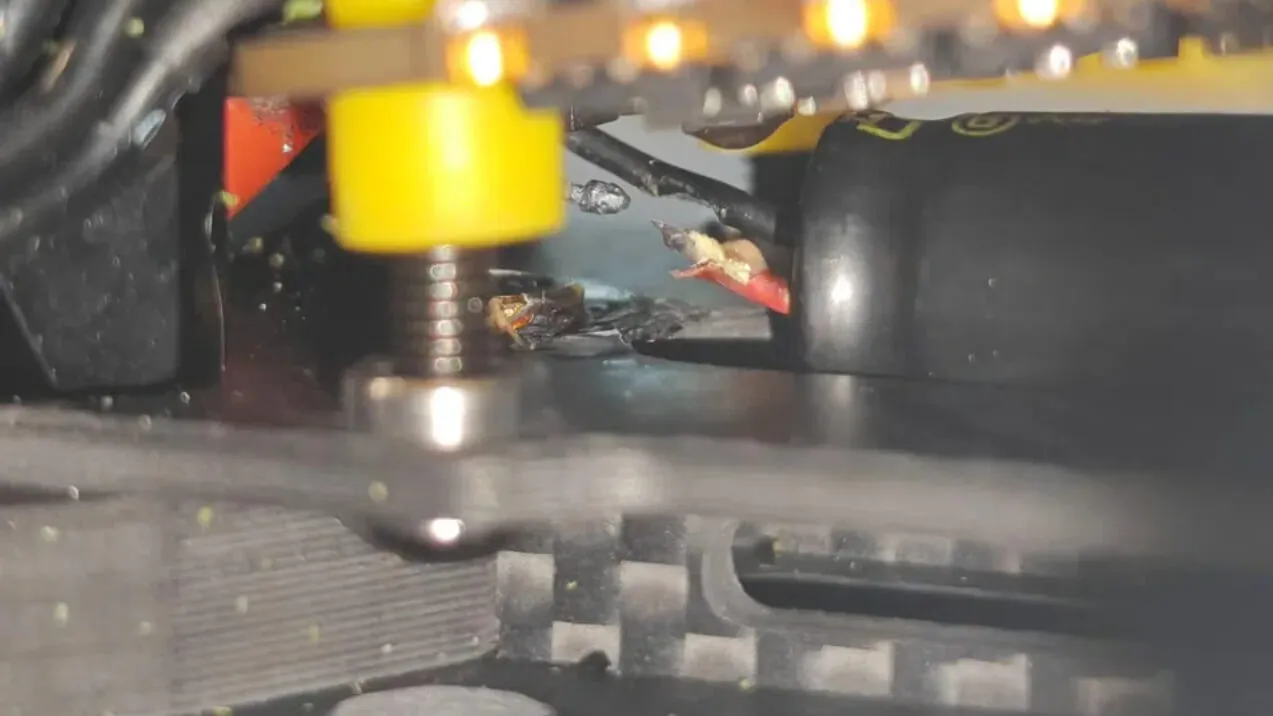

- Short Circuits – If the capacitor’s leads or body make direct contact with the carbon fiber frame, it could cause a short circuit since carbon fiber is conductive. This may result in power failure or even permanent damage to your drone’s electronics.

- Electrical Noise & Interference – Capacitors help filter voltage spikes and noise in the power system. If they touch the frame, improper grounding or unintended electrical paths could introduce noise or instability in the system, affecting video transmission (VTX) and flight controller performance.

- Physical Damage – The vibrations and impacts during flight or crashes can cause the capacitor to rub against the frame, leading to wear on the insulation, potential breakage, or even desoldering from the PCB.

How to Avoid This:

- Use Heat Shrink Tubing – Cover the capacitor leads with heat shrink to insulate them.

- Secure with Zip Ties or TPU Mounts – Fix the capacitor away from the frame using a zip tie, double-sided tape, or a 3D-printed TPU holder.

- Proper Positioning – Mount the capacitor in a location where it won’t move or touch the frame, such as tucked next to the battery lead or secured to the ESC.

Keeping capacitors properly insulated and secured will ensure the longevity and reliability of your FPV drone’s power system.

Is It Bad to Add Too Many Capacitors for Drone?

In your circuit, you should carefully regulate the capacitance and inductance if you are filtering signals inside a specific frequency band. However, since we are only working with DC voltage and a low pass filter, you won’t be able to “over-filter” the DC voltage, thus you are free to use as much capacitance as you like without running into any issues. In actuality, the stronger this low pass filtering is in your drone, the more capacitors it contains. As long as you have space to install them, feel free to use as many drone capacitors as you like.

Do Capacitors Wear Out?

Due to elements like high temperatures and high voltage stress, electrolytic capacitors used in FPV drones have a finite lifespan. An electrolytic capacitor’s capacitance may drop and it may leak or bulge as it ages. The power supply may become unstable and noisy as a result, which could impair the devices’ functionality. Drone capacitors should be inspected and replaced on a regular basis; even if they appear to be “ok,” it may still be worthwhile to do so.