Brushless drone motors have revolutionized the world of brushless electric motors, offering numerous advantages over brushed motors. In this comprehensive guide, we will explore the principle of operation of brushless drone motors, highlighting their key features, benefits, and applications. Whether you are an enthusiast looking to build your own drone or someone interested in understanding the inner workings of these motors, this guide will provide you with the essential knowledge you need.

What are Brushless drone motors?

At its core, a brushless drone motor is an electric motor that operates on direct current (DC) with a rotor composed of permanent magnets. Unlike brushed motors, brushless drone motors do not rely on sliding electrical contacts (brushes) on the motor shaft for operation. Instead, the commutation of the current in the stator windings and the resulting variation in the magnetic field are controlled electronically. This design eliminates mechanical resistance, reduces the risk of sparks at high speeds, and significantly minimizes the need for periodic maintenance.

What Are Brushed Motors?

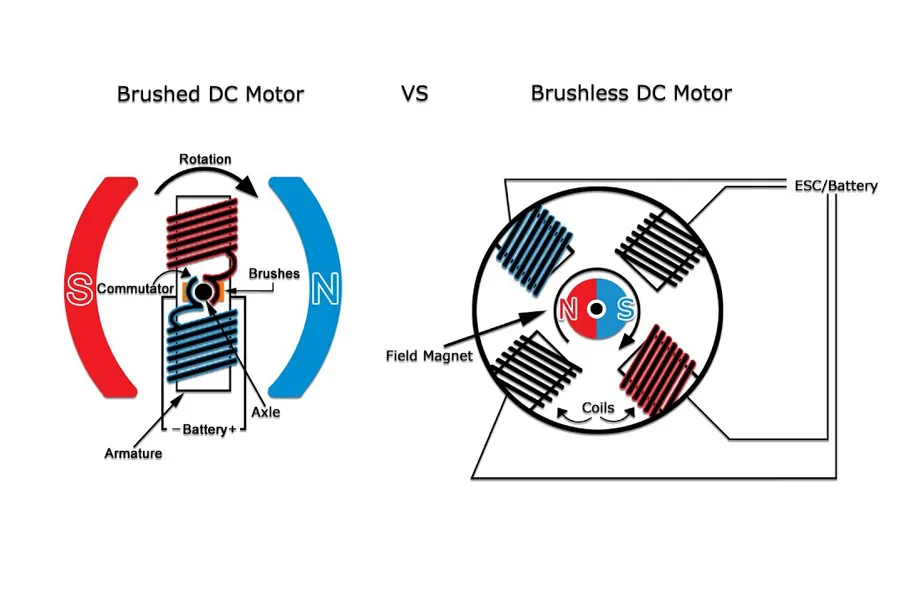

Brushed motors are a traditional type of electric motor commonly used in basic drones and small electronic devices. They consist of a rotor with windings and a stator with magnets. The motor uses brushes made of carbon or metal that maintain physical contact with a commutator—a rotating switch on the rotor.

As electricity flows through the brushes to the commutator, it reverses the current direction in the rotor windings, creating a magnetic field that interacts with the stator magnets to produce rotation. This mechanical switching method enables the motor to spin continuously.

However, because the brushes constantly rub against the commutator, friction occurs, leading to wear and tear over time. This limits the motor’s lifespan and efficiency. Brushed motors are simple, inexpensive, and easy to control but tend to have lower performance compared to brushless motors.

What is the difference between Brushed and Brushless Drone Motors?

Brushed motors operate using a mechanical system that includes brushes and a commutator. The brushes are physical contacts that transfer electrical current to the spinning rotor windings. As the motor rotates, the commutator switches the current direction in the rotor coils to generate a continuous rotational force (torque). However, because the brushes and commutator are constantly in contact, this creates friction which leads to energy loss, heat generation, and gradual wear of the brushes. This wear limits the overall lifespan of brushed motors and requires regular maintenance or replacement of components. Additionally, the friction produces audible noise, and brushed motors typically have lower efficiency compared to their brushless counterparts.

In contrast, brushless motors completely eliminate the need for brushes and the commutator. Instead, the rotor is equipped with permanent magnets, and the stator contains the electromagnets that are electronically controlled to sequentially energize and create a rotating magnetic field. This electronic commutation means there is no physical contact inside the motor, resulting in significantly less friction and wear. Consequently, brushless motors offer higher efficiency—translating to better power utilization and longer flight times—as well as quieter operation. Their reduced mechanical wear also means a much longer lifespan and lower maintenance needs.

Here is a Summary of the Key Differences

| Feature | Brushed Motor | Brushless Motor |

|---|---|---|

| Commutation Method | Mechanical (brushes + commutator) | Electronic (no brushes) |

| Internal Friction | High (due to brush contact) | Low (no physical contact) |

| Efficiency | Lower (energy loss due to friction) | Higher (better power transfer) |

| Noise Level | Noisier (brush friction noise) | Quieter operation |

| Maintenance | Requires brush replacement and upkeep | Minimal maintenance |

| Lifespan | Shorter (brush wear limits life) | Longer (durable design) |

| Cost | Generally cheaper upfront | More expensive but cost-effective long-term |

Working Principle

- Brushed motors use brushes and a commutator to switch current direction in the rotor windings, causing rotation.

- Brushless motors have no brushes; they use electronic controllers to power the stator coils, while the rotor contains permanent magnets.

Friction and Wear

- Brushed motors have physical contact between brushes and the commutator, causing friction, wear, and energy loss.

- Brushless motors eliminate brushes, significantly reducing friction and mechanical wear.

Efficiency and Performance

- Brushed motors are less efficient with more energy lost to friction, resulting in shorter flight times.

- Brushless motors offer higher efficiency, better power utilization, and longer flight duration.

Noise Level

- Brushed motors generate noticeable noise from brush friction.

- Brushless motors run quietly with minimal noise.

Maintenance and Lifespan

- Brushed motors require regular brush replacements and more maintenance.

- Brushless motors have longer lifespans and need minimal upkeep.

Cost

- Brushed motors are cheaper upfront, often found in entry-level drones.

- Brushless motors cost more initially but are more cost-effective over time due to durability and performance.

Overall, brushless motors deliver superior performance, reliability, and longevity, making them the preferred choice for most modern drones, especially in demanding applications like racing, freestyle flying, and professional cinematography.

How Brushless Drone Motors Operate?

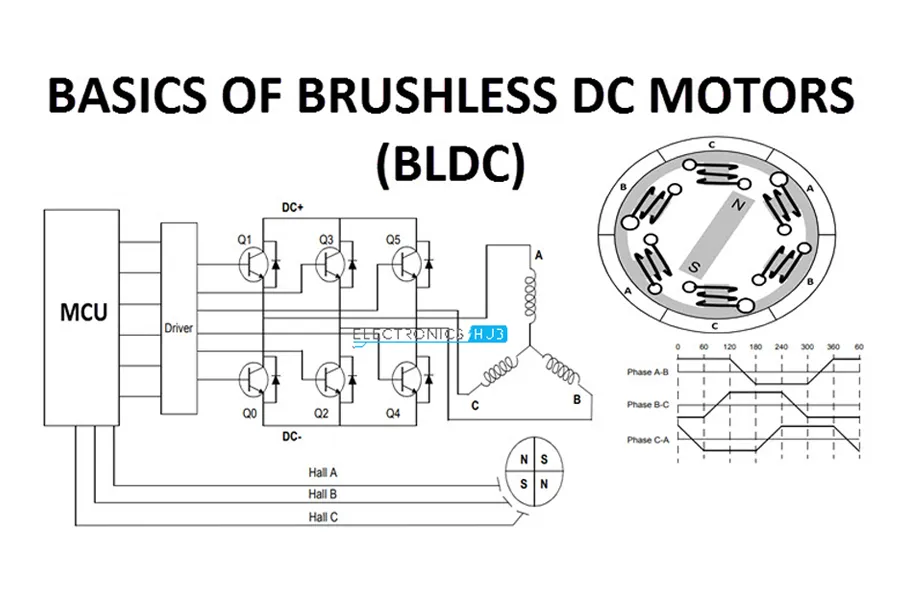

The principle of operation of brushless drone motors involves the interaction between the rotating magnetic field generated by the permanent magnets on the rotor and the variable magnetic field produced by the windings on the stator. To achieve rotation, an electronic circuit, typically controlled by a microcontroller, commutates the current flow, causing the magnetic field to change direction and induce rotation. Precise rotor position detection, often accomplished using Hall effect sensors or resolvers, allows the controller to determine the required magnetic field orientation accurately.

Key Advantages of Brushless Drone Motors

Brushless drone motors offer a range of benefits that make them highly desirable for various applications. Let’s explore some of the key advantages:

Longer Lifespan and Reduced Maintenance

One of the primary advantages of brushless motors is their extended lifespan. With no brushes to wear out, these motors can operate reliably for extended periods without the need for frequent maintenance. This longevity translates to cost savings and improved overall durability.

Enhanced Efficiency and Performance

Brushless motors operate at higher efficiency levels compared to brushed motors. The absence of rotor-generated magnetic fields allows brushless motors to achieve optimal performance and energy conversion. This efficiency improvement results in reduced power consumption, longer battery life, and improved overall system performance.

Quieter Operation and Reduced Electromagnetic Interference

The elimination of brushes in brushless motors significantly reduces noise during operation. The absence of physical contact between the brushes and the commutator eliminates the primary source of electromagnetic interference found in brushed motors. This reduction in noise and electromagnetic interference makes brushless motors ideal for applications requiring quiet and interference-free operation.

Precise Control and Variable Speeds

Brushless motors offer precise control over speed and torque, allowing for smoother operation and better performance. The electronic commutation system enables accurate adjustments, resulting in reduced inertia and energy consumption. This level of control is especially crucial in applications where precise movements or varying speeds are required.

Compact Size and High Power-to-Weight Ratio

Brushless motors are known for their compact design and high power-to-weight ratio. The absence of brushes and the use of permanent magnets on the rotor contribute to a more efficient use of space. These motors are particularly suitable for applications where size and weight are critical factors, such as drones, electric vehicles, and robotics.

Applications of brushless electric motor

brushless electric motors find applications in various industries and products. Let’s explore some notable examples:

Brushless motors for drones

The rise of unmanned aerial vehicles (UAVs) and the drone industry has significantly benefited from brushless electric motor technology. Brushless motors for drones provide the necessary power, efficiency, and control required for stable flight and maneuverability. Whether it’s a DIY drone kit or a professional-grade FPV racing drone, brushless motors for drones are the preferred choice due to their reliability and performance.

Electric Vehicles

The automotive industry has embraced brushless electric motor for electric and hybrid vehicles. These motors offer high efficiency, precise control, and compact size, making them ideal for powering electric cars, motorcycles, and other electric transportation systems. The improved energy conversion and reduced maintenance contribute to the overall viability of electric vehicles as a sustainable mode of transportation.

Industrial Automation and Robotics

In industrial automation and robotics, brushless electric motor provide the necessary torque, speed control, and reliability for precise movements and heavy-duty applications. From robotic arms on assembly lines to automated machinery, brushless motors offer superior performance and longevity compared to their brushed counterparts.

HVAC Systems and Appliances

Brushless electric motor has found their way into heating, ventilation, and air conditioning (HVAC) systems, as well as household appliances such as refrigerators and washing machines. These brushless electric motors provide efficient and reliable operation, contributing to energy savings and improved performance.

Selecting and Using Brushless Electric Motors

When choosing a brushless electric motor for your specific application, several factors need to be considered:

Power and Torque Requirements

Evaluate the power and torque requirements of your application to select a brushless motor that can deliver the necessary performance. Consider factors such as load demands, speed requirements, and any additional power needs specific to your application.

Motor Size and Weight

Take into account the available space and weight constraints when selecting a brushless motor. Compact and lightweight designs are advantageous in applications where size and weight are critical factors, such as drones or portable devices.

Controller and Flight Control System

Ensure compatibility between your brushless motor and the associated controller or flight control system. A well-matched system ensures optimal performance and reliable operation.

Quality and Reliability

Choose brushless motors from reputable manufacturers known for producing high-quality and reliable products. Consider factors such as warranty, customer reviews, and industry reputation when making your selection.

Conclusion

Brushless electric motor has revolutionized various industries, offering numerous advantages over traditional brushed motors. The absence of brushes, improved efficiency, precise control, and extended lifespan make brushless motors the preferred choice for applications ranging from drones to electric vehicles and industrial automation. By understanding the principle of operation and considering key selection factors, you can harness the power of brushless motors in your projects and enjoy the benefits they offer. Embrace this technology, and unlock a new level of performance and reliability in your endeavors.

Additional Information:

Principle of operation of brushless motors. In brushless motors: the field produced by the rotoric permanent magnets is rotating; the rotating field produced by the currents circulating in the three stator windings is maintained on average in advance of electrical 90° by the action of the control on the inverter powering the motor.

wikipedia:https://en.wikipedia.org/wiki/Electric_motor

Author:volarelettrico

Article in Italian version: https://volarelettrico.altervista.org/author/volarelettrico/